WHEN PRECISION MATTERS MOST –

TRUST A LEADER

Whether you need a laser, laser sub-system, or a complete manufacturing machine, you can depend on Coherent for precision, quality, process development, and exceptional after-the-sale support. Drawing on the broadest portfolio of laser and laser-related technologies anywhere, Coherent brings decades of experience, technical innovation, and support commitment to deliver the optimum solution to your medical device manufacturing challenges.

Intraocular Lens

Laser cutting

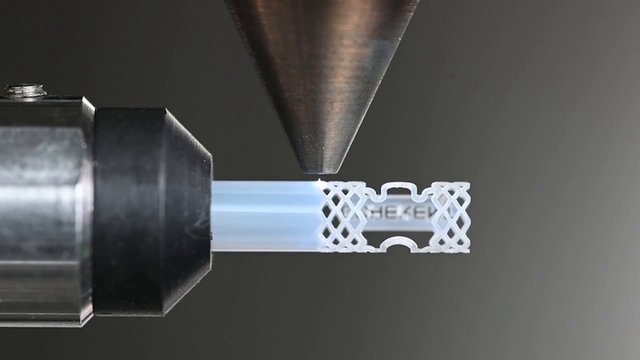

Polymer Stents

Laser cutting

Nitinol Stents

Laser cutting and laser welding

Polymer Tubes / Catheder

UV laser marking

Insulin Tubes

Laser cutting

Endoscopes

Laser cutting, laser welding, laser marking

Thrombectomy

Laser cutting and laser welding

Dental Implants

Metal 3D printing

Pacemaker

Black Marking and laser welding

Biopsy Forceps

Laser welding and laser marking

Hypotube

Laser cutting and laser ablating

Hip Rasp

Laser cutting and laser marking

THE WORLD OF

LASER APPLICATIONS

Laser Welding

High Strength Connection of Delicate Components

Coherent laser welding systems deliver better results when joining delicate or heat sensitive parts, or when ultra-fi ne seams are required. The fast and accurate welding process results in a hermetic seal with up to 80 % spatter reduction and unmatched process stability, reducing the need for costly post-processing.

Laser Cutting

Cutting Widths Below 20 μm

Coherent laser-based systems for tube and fl at cutting are ideal for manufacturing devices and instruments that involve the production of fi ne features in temperature sensitive materials, such as nitinol. Based on an ultrastable granite platform, these versatile systems deliver precise cuts in a wide range of complex geometries with almost no burrs or edge hardening. Plus, a powerful software interface streamlines job setup and production.

Laser Structuring

Custom-Made Surfaces

The laser is an unmatched tool for creating microstructures. Coherent systems can produce features smaller than 15 μm through controlled ablation in a variety of materials, including various polymers utilized in the production of catheters. Surface textures can be optimized for the biological interaction of implants, and die casting molds can be produced using these systems.

THE WORLD OF

LASER APPLICATIONS

Laser Marking

Biocompatible and Durable

There are almost no technical limits to the marking outline and content enabled by Coherent systems, whether it is marking implants, medical devices, or surgical instruments with data matrix codes and UDI marks to ensure traceability. They support shallow marking, 3D marking, grayscale marking, corrosionresistant black marking, and micro marking with character dimensions as small as 10 μm.

Additive Manufacturing

3D Metal Printing

3D metal printing enables rapid production of implants, clasps, partials and telescopic components, eliminating hours of traditional fabrication. Parts can be created directly from CAD/CAM designs in Co-Cr, titanium and most other metals. The Coherent CREATOR is a fully automated system that enables superior personalized dental products and other devices at lower cost, benefiting both the manufacturer and the patient.

LASER SYSTEMS FOR MEDICAL DEVICE

MANUFACTURING

Coherent has been developing laser solutions for medical device manufacturing for more than three decades. In our application labs we work with a whole range of laser systems, latest fi ber and ultrashort pulse laser technology. Especially for the medical device industry.

Several hundred new applications are evaluated each year. We invest heavily in faithful and long-lasting partnerships with our customers and leading research institutes. Coherent is a global operating company with production, sales and service sites all over the world. An essential precondition to support distributed manufacturing concepts, for instance research and product design in the USA and large scale production in Asian countries.