From hearing aids to steering wheels, the applications of FlexTune™ 3D Printed elastomers are endless. Our technology focuses on printing rubbery, elastic materials with unparalleled durability.

Our 3D printed elastomers perform just like traditional polyurethanes. If a mass-produced application or part requires a polyurethane, styrenic block copolymer, thermoplastic elastomer, EPDM or PVC today, chances are that our printable polyurethanes will work just as well or better.

Right now we are only just beginning to explore and develop for the breadth of applications that will be made possible by our Flextune™ technology, but the commonalities will be soft touch, flexibility, elasticity and shape retaining durability. Below are some of the applications for FlexTune™

Applications:

Rubber handles and grips

Insoles

Steering wheels

Tires and wheels

Hearing aids or other medical devices

A Resin with Medical Applications:

A customer approached us seeking a material that could meet specific regulatory requirements and have a characteristic of increasing flexibility during the temperature increase from room to body temperature. We were able to develop a casting resin to meet their requirements.

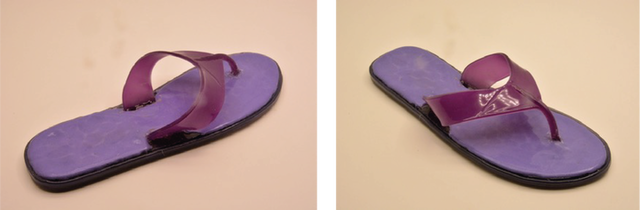

Partnering with a producer of consumer goods, we identified portions of the mass-produced part where printing directly on top would bring cost-effective personalization and furnish a custom product for their customers.

Material Customization: Chromatic 3D Materials’ printing technology allows for changes in hardness in the printed materials and still provides uniformly solid parts. In collaboration with the customer, we develop solutions that allow for a material that softens at body temperature, providing a better fit, while being structurally supportive. In another application we designed a process that allowed two hardnesses to be printed in one consecutive part.

THE ACHIEVEMENT: The Chromatic 3D Materials’ technologies afford the benefits of 3D printed geometries with the added benefit of the material flexibility of a casting process.

Variable Hardness within the Same Print

Rapid Durable Part Manufacturing:

COVID-19 Case Study

PEEP Valve Adapter

The Solution

Click boxes above for more infomation

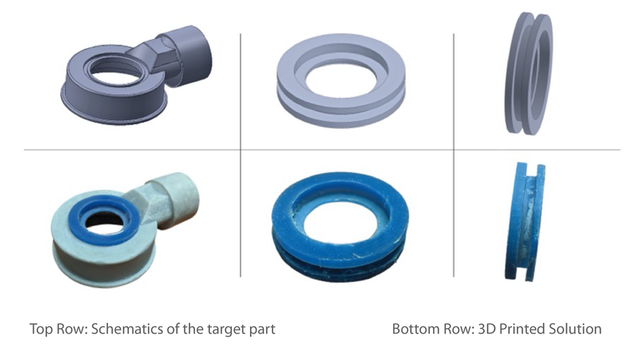

Case Study: PEEP VALVE ADAPTER

During the early days of the Covid-19 crisis, Chromatic 3D was approached with an urgent need for a critical ventilator part known as a Positive End Expiratory Pressure, or PEEP, valve adapter.

The part had gone out of supply due to the increased demands of the global pandemic.

We quickly designed a solution which employed a Digital Mold™ for Reactive 3D printing™ combined with stereolithography (SLA), that would satisfy the need without employing costly injection mold processes.

WHY LIQUID REACTIVE 3DTM PRINTING?

Chromatic 3D Materials was tasked with satisfying a unique combination of requirements with an inexpensive, fast, just-right solution.

Speed: Traditional manufacturing injection molds were not available. The production of new injection molds was cost prohibitive and had lead times likely exceeding the peak of COVID-19 infections when the PEEP valve assembly would be most needed.

Material Properties: Flexible, airtight and rugged, the adapter part has very specific requirements in that the seal must be highly flexible with a Shore A Hardness of 55 to produce an air-tight seal. It also has to be rugged enough to withstand repeated assembly and disassembly by medical personnel under hasty conditions. Liquid Reactive 3D Printing™ provides uniform parts suitable for the PEEP valve assembly. Other 3D printing technologies cannot produce a flexible seal with these requirements.

THE ACHIEVEMENT: The Chromatic 3D Materials team, in close collaboration with the customer, developed a novel solution employing two different printing technologies: Liquid Reactive 3D Printing™ for the seal, and SLA for the body, to meet the design specifications of the customer.

Variable Hardness within the Same Print

Geometric customization can offer a perfect fit to a patient’s body for many prosthetic, orthopedic and acoustic applications. Additional comfort can also be afforded through customization of material for different feels and varying rigidity in different sectors of the same part. All this benefits a patient’s comfort and increases overall benefit through improved user adoption.

Traditional casting-based manufacturing techniques offer geometric and material customization through labor intensive, high cost processes which leave a large segment of customers unable to access the best possible solution. Current 3D printing technologies can offer geometric customization at a reasonable price but suffer from a lack of material customization, as well as durability, in these high wear applications.

Printing on and around anything from textiles to Electronics

The Opportunity:

Chromatic 3D Materials’ flexible yet durable resins, technologies and techniques offer wide versatility in the arenas of geometric customization, material properties and speed of production. This combination affords some exciting future applications.

Imagine for a moment: We have robots that talk, walk, run, and manipulate objects. Recent advances have also been made in simulating the five human senses including hearing, sight and even smell. Robotic touch, however, remains a persistent conundrum especially as it relates to grasp. The feedback loop necessary to support a robot or prosthetic gripping an object tightly enough to hold it yet also not crush it has remained an elusive and complex challenge. It is this ability to simulate the sense of touch which might be solved by sensors embedded in an affordable multi-hardness 3D print which is then linked to the latest actuator technology.

WHY LIQUID REACTIVE 3DTM PRINTING?

Chromatic 3D Materials’ flexible yet durable resins, technologies and techniques offer wide versatility in the arenas of geometric customization, material properties and speed of production. This combination affords some exciting future applications.

Imagine for a moment: We have robots that talk, walk, run, and manipulate objects. Recent advances have also been made in simulating the five human senses including hearing, sight and even smell. Robotic touch, however, remains a persistent conundrum especially as it relates to grasp. The feedback loop necessary to support a robot or prosthetic gripping an object tightly enough to hold it yet also not crush it has remained an elusive and complex challenge. It is this ability to simulate the sense of touch which might be solved by sensors embedded in an affordable multi-hardness 3D print which is then linked to the latest actuator technology.

Multi Material Printing: The technology used by Chromatic 3D Materials allows for multi-material printing. What is meant by this is that a part may be printed with hardness differentials which may be pressed (literally!) into service as varying levels of feedback triggers for robotic sensors. Additionally, our resins can be custom fitted and printed on to a substrate such as metal, plastic or textiles. Imagine a prosthetic limb, made for a quickly growing child, with sensors embedded at the extreme end to simulate touch and facilitate grasp.

THE ACHIEVEMENT: We are working on bringing this vision to life. We will combine our resin’s ability to print on a variety of flexible textiles and around structural fixtures and electronics, such as actuators with the customization and material knowledge our special printing processes can produce in order to offer the ability to add a form of robotic “touch” on to traditional robots as well as prosthetics.

The Chromatic 3D Materials technologies allow a new level of flexibility in production processes. We can augment your current processes, materials and methods with Reactive 3D TM Printing and integrate seamlessly with your technology.