Motion control specialist turns 50

It all started in 1956 with the Hungarian uprising….

Stephen, an 18 year old trained toolmaker at this time, was on the front line and supplying the insurgents with food. When the uprising was put down with the help of the Russian army, he had to leave his Hungarian home for fear of his security. On a foggy night, he hid in a hay cart and crossed the Austrian border undiscovered. It was easy to see that there was no longer any hope in Hungary, he later commented.

From toolmaker to designer of positioning systems

From Austria, the toolmaker, via detours, came to the USA with a few dollars in his pocket on a ship. After only a few months there he had his American high school diploma in his pocket - his Hungarian school leaving certificate had not been recognised. He started his professional career at Goerz Optical Co. in Pittsburgh as a designer. At that time, Goerz Optical manufactured optical lenses and systems for NASA, among others. The products in which he participated as a designer included test devices for highly developed inertial control systems in the aerospace industry. His sense of high precision in production already developed here. However, since his previous Hungarian degrees were not recognised, Botos took evening courses in mechanical engineering from the University of Pittsburgh, while working as a designer. Immediately after completing his mechanical engineering degree in 1969, he and two of his engineering colleagues teamed up and founded Aerotech, Inc. in Pittsburgh in 1970.

Aerotech, much like Microsoft, came from humble beginnings in that the company also started life in a garage. The first development was a $ 20,000 prototype location system for industrial use. The first positioning system manufactured was a simple two-axis electromechanical application and was available for around $ 300.

The first renowned customers such as Du Pont and IBM opened the door to industry for Aerotech. According to company founder Stephen Botos, Aerotech was the first company to use closed-loop servo technology for its linear positioning systems. This was four times the performance of conventional stepper systems.

Excellent lifetime achievement

In the course of his working life, this mechanical engineer was able to register eleven US patents and received numerous awards. He is particularly proud of the “ACMS Benjamin Rush Award”, which was given to him for the further development of intraocular lenses to improve eyesight. He was also awarded the ASPE Lifetime Achievement Award by the American Society for Precision Engineering in 2019. This prestigious award is only given annually to one person who has made an important contribution in the field of precision engineering.

Aerotech precision technology in use worldwide

Aerotech saw rapid growth in the first few years. The first patent and the subsequent introduction of a manual optical holder contributed significantly to this. This enabled an extremely high resolution as well as a large range of motion. The initial manual positioners were soon followed by the first electronic controls and driven positioners. As a result, demand in the commercial sector for precision manufacturing and testing technology increased noticeably. The first subsidiaries in the United Kingdom and Germany in the 1980s heralded international expansion. Thanks to the product range of positioning systems that has now been achieved, Aerotech was able to cover a wide range of industries, from medical technology and life science applications, in photonics, automotive, data storage, laser processing, aerospace, as well as verification and testing to assembly. With subsidiaries in Taiwan and China and a joint venture in Korea, the company entered the growing Asian market and thus in electronics manufacturing, semiconductor and flat screen production. New air-bearing and linear motor-based positioning applications ensured the required high precision and throughput in these areas.

From it’s early beginnings in a Pittsburgh garage to today, Aerotech has worked out a solid niche in the field of high-precision motion control. “With our wide range of products, we specialise in machining in the nanometre range”, explains Simon Smith, European Director Aerotech. The vertical range of manufacture is enormous; almost all components from the positioning system to interferometers and drives to motion control and software are mainly manufactured by Aerotech itself.

The company has now grown to around 500 employees worldwide but has remained a family run company, something that has always been important to the Botos family. Together with son Mark Botos, who heads the company as president, Stephen’s other son Steve Botos also works for the company as Chief Officer Communication & Strategy.

1970 - Founded in Pittsburgh, PA

1973 - First patent for coarse / fine positioning

1974 - Expansion of the company area to 18,000 square meters

1970s - Introduction of the first ball screw positioning systems with advanced linear servo drives

1979 - Foundation of Aerotech GmbH, Germany and expansion at the headquarters in Pittsburgh to 54,500 square meters

1981 - Foundation of Aerotech Ltd, UK

1980s - Introduction of microprocessor-based motion controls

1990 - PC bus based motion controller

1992 to 1993 - Introduction of brushless linear and rotary servomotors

1994 - The first air-bearing positioning systems

1995 - ISO9001 certification.

2001 - Introduction of Automation 3200, the first software-based 32-axis motion, vision and I/O control

2011 - Foundation of Aerotech Taiwan

2013 - Foundation of Aerotech China

2013 - Moving Aerotech Ltd from Aldermaston to Basingstoke into newer, more purpose built facility better able to cope with company growth.

2017 - Majority stake in Alle-Kiski Industries

2017 - Foundation of a joint venture in Korea

2017 - Moving Aerotech Germany from Nuremberg to Fürth. New building with the most modern technology equipped measuring room and assembly area for customer-specific assembly

Aerotech headquarters in Pittsburgh

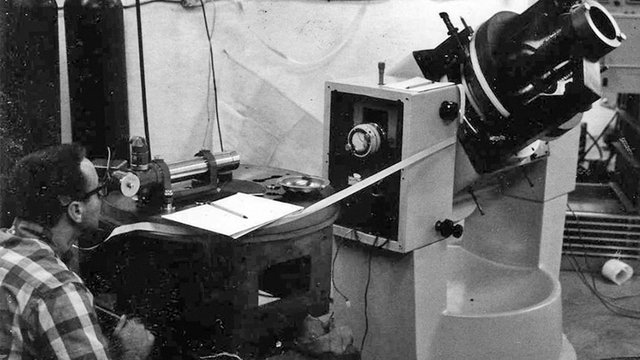

First patent

Company founder Stephen J. Botos before his first patent in 1973: a positioning mechanism for coarse and fine adjustment

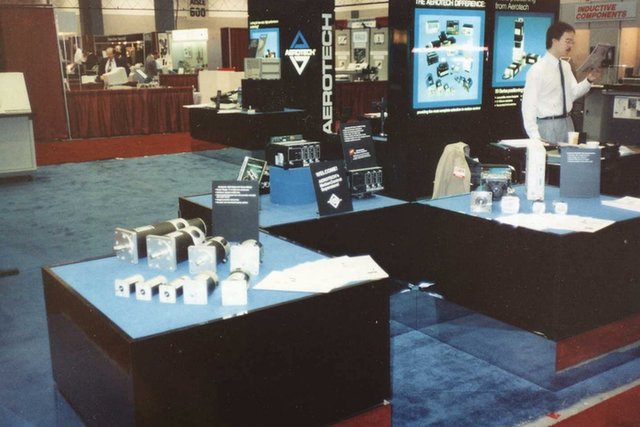

Trade fair appearance from the early years of Aerotech

From left to right Steve Botos (Chief Officer Communication & Strategy), Stephen J. Botos (Partner) and Mark Botos (President)

Motion control and positioning systems

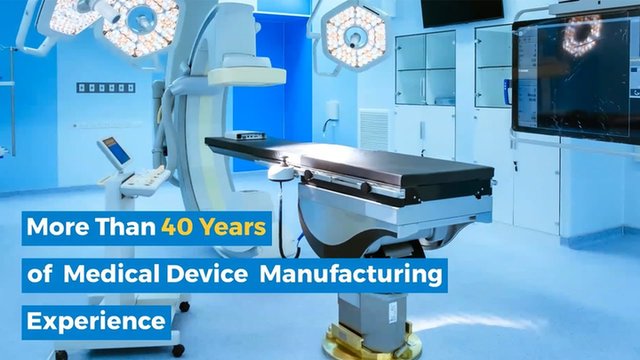

Aerotech has a wide range of products for customers in industry, science and research, including in medical technology, life science applications, semiconductor and flat screen production, in the areas of photonics, automotive, data storage, laser processing, aerospace, electronics manufacturing, as well as verification and testing, up to assembly.

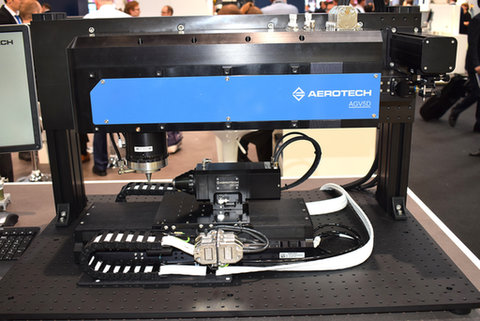

AGV5D

One of Aerotech’s current product highlights is the AGV5D 5-axis laser scanner for precise microlaser processing, especially in medical technology, microelectronics and component manufacturing in the automotive industry.

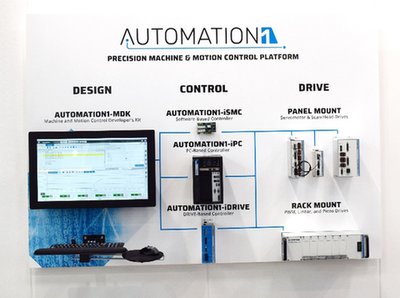

Automation1

The latest software highlight from Aerotech is the revolutionary control platform “Automation1” for precision movement and machine control.

Aerotech – Dedicated to the Science of Motion

Aerotech Inc., headquartered in Pittsburgh, USA, is a private, family-owned, mid-sized company. Founded in 1970 by Stephen J. Botos, Aerotech designs and manufactures the world's most powerful motion control and positioning systems for industrial, scientific and research customers. In the spirit of a family business, the owners continue to attach the utmost importance to an open and trusting relationship with customers, business partners and employees.

In the UK, Aerotech has a sales and service office in Ramsdell, near Basingstoke. The customer-specific assembly of the positioning systems for the entire European market takes place in the branch in Fürth near Nuremberg.

The innovative and high-precision motion solutions meet all the critical requirements needed for today's demanding applications. They are used wherever high throughput is required, e.g. with medical devices and life science applications, in semiconductor and flat screen production, in photonics, automotive, data storage, laser processing, aerospace, electronics manufacturing, as well as in testing and inspection through to assembly.

Aerotech provides world-class technical support and service with its advanced analysis and diagnostic capabilities. If a standard product is not suitable for an individual application, Aerotech’s many years of expertise and experience enable the manufacturer to supply special motion components and systems. The manufacturing capacity for custom applications is complemented by experience in supplying systems for vacuum and clean room operation

Aerotech has full-service offices in Germany (Fürth), United Kingdom (Ramsdell), China (Shanghai City) and Taiwan (Taipei City). Aerotech currently employs approximately 500 people worldwide.

Aerotech Ltd

The Old Brick Kiln,

Ramsdell

Tadley, Hampshire,

RG26 5PR U.K.

Uwe Fischer

T: +44 1256 855055