MK Fluidics is roll to to roll (R2R) company having proprietary technology for high accuracy laser cutting of nano- and micropatterned shims and laser welding them to sleeves to be used in R2R nano imprinting manufacturing processes.

MK Fluidics is offering also polymer microfluidic prototyping, product development and transfer to production.

Our narrow web R2R printing machine SAMPO Lab2Fab is excellent tool for development and manufacturing of printed electronic devices and microfluidic diagnostic tests.

MK Fluidics is roll-to-roll (R2R) company developing new products, technologies, processes and equipments for R2R manufacturing.

Solutions

Narrow web printing machine SAMPO Lab2Fab for R&D and manufacturing. Modular sturdy design that provides a flexible tool development and manufacturing of printed electronic and microfluidic devices.

Services

Polymer microfluidic prototyping process, microfluidics product development, transfer to production, and manufacturing. Ni shim high accuracy cutting, recombination and welding to larger shims and cylinders for R2R processes.

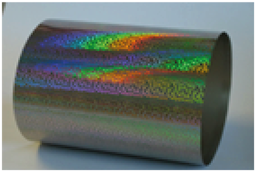

Shim welding

One of our products is high accuracy laser cutting of shims, followed by recombination of several shims into one large shim by laser welding, thus we are capable of forming one large area micro-patterned nickel (Ni) shim to overcome the typical size limitations of masters for Ni electroplating, or the electroplating process itself.

Our core technology is manufacturing of micro-/nanopatterned hollow Ni shim cylinders (or sleeves as we call them), where we recombine high accuracy laser cutted micro-/nanopatterned Ni shims into a single row and weld ends together accurately, and thus form a micro-/nanopatterned hollow cylinder with extremely tight circumferential tolerances.

These ‘sleeves’ are then assembled at production site easily onto a print cylinder without any double sided adhesive tapes. This technology was developed in early 2000 and has been in full production since 2009. We have produced over 500 sleeves.

Application examples:

*UV-NIL

*Hot embossing

*Microfluidics

*Optics

*Nanopatterning

Capabilites:

Max. size 2000mm x 2000mm (diameter 600mm)

Ni (shim) thickness 100-300μm

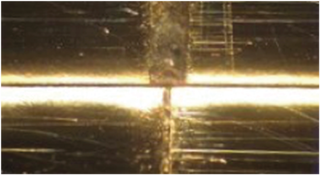

Welding seam width (standard <250μm, enhanced <30μm) (see picture above)

Accuracy <10μm

Microfluidic prototyping

Polymer microfluidic prototyping, development, transfer to production, and manufacturing. In our prototyping processes we use the same processes, hot embossing, and laser cutting, and materials to manufacture prototype parts as we do to produce volume requirements. Benefits of our prototyping process:

•Multiple projects or multiple designs in one batch

•No machined channels

•Materials and surface quality are similar to molding.

•Rapid turn around time.

•Easy transfer to production.

Typical Specifications

Number of different designs in one run:

up to 30 (microscope slide size)

up to 12 (credit card size)

up to 6 (microtiter plate size)

Number of layers: 1 to 2

Total available area for designs: 20cm x 40cm

Lot size: 30 - 500 chips

(more on request)

Channel width: 50 μm to 400μm (±15%)

Channel depth: 35μm to 55μm (±10%)

Materials: Thermoplastic polymers

Material thickness: 125 μm, 375 μm

Access hole size: 1 mm to 5 mm (±10%)

Surface roughness: In channel Ra<20nm

Outside Ra<80nm

We offer also prototyping services for 3D printed microfluidic with dedicated microfluidic 3D printer.

WATCH HERE

WATCH HERE

Solutions

Narrow web R2R converting and printing machine

The SAMPO Lab2Fab converting and printing machine is modular R2R machine, which is built on a rigid mechanical structure, which has room for different types of printing units such as screen, gravure, flexo, hot embossing and various coating technologies and nanoimprinting. Between the printing units there is room for different types of dryer/heating modules.

The SAMPO Lab2Fab converting and printing machine has an easy to use via versatile touch screen user interface for the control of speed, configuration and other important parameters.

The SAMPO Lab2Fab converting and printing machine has lamination unit to support the R2R packaging of the printed web. All machines are customized but are built using standard modules.

Applications include:

•OPV, OSC, OLED

•Sensors

•Printed electronics and optics

•Microfluidics

•Printed rapid tests

•Medical electrodes

WATCH HERE

About us

MK Fluidics Ltd, established in 2009, is a spin off from VTT Technical Research Centre of Finland, which is the biggest multitechnological applied research organisation in Northern Europe. All expertise, facilities and technologies originate from VTT’s Printed Intelligence research program started in late 90’s.

Technology and manufacturing are based on roll-to-roll printing of microfluidics, electronics, optics and optoelectronics, and their integration to lab-on-a-chips and biosensors for applications in diagnostic, life science, water quality and purification, and bioprocessing.

The company is also capable to manufacture high accuracy micro and nanostructured Ni-shims for hot embossing and nano imprinting. Ni shims are cutted to exact dimensions and welded to sleeves for easier installation onto print cylinder. In addition to roll-to-roll production, rapid prototyping tools are used for smaller series development and manufacturing.

Team

President, CTO Markku Känsäkoski

More than 25 years expertise in R&D and product design of optical analytical measurement systems, components, and modules, project management, technology strategy and roadmapping VTT). Nearly 20 year expertise on printed microfluidics, printed biosensors, printed electronics and optics (VTT and MK Fluidics)

VP Production,

Jaakko Pennanen

More than 25 years hands on and management expertise in manufacturing of electronic components and modules, printing based manufacturing and equipment development for printed microfluidics, printed biosensors, printed electronics and optics

(VTT, LK Products and MK Fluidics)

Business unit director

Matti Aaltomaa

More than 30 years of hands on and management in manufacturing of electronic components and modules, and automation (Nokia and MK Fluidics).

Contact

MK Fluidics Ltd

Hautakorventie 15A

90620 Oulu

Finland