MPS Microsystems develops and manufactures high-precision, high-performance and very efficient electro-mechanical microsystems. Managing the miniaturisation and integration of functions in small volumes, MPS Microsystems provides solutions that meet specific customer requirements. MPS Microsystems also offers a range of standard products, such as linear bearings and ball screws, as well as technological platforms that can be configured to match individual specifications.

Our strengths

- Innovation

- Performance & miniaturisation

- Service quality

- Reliability

1

2

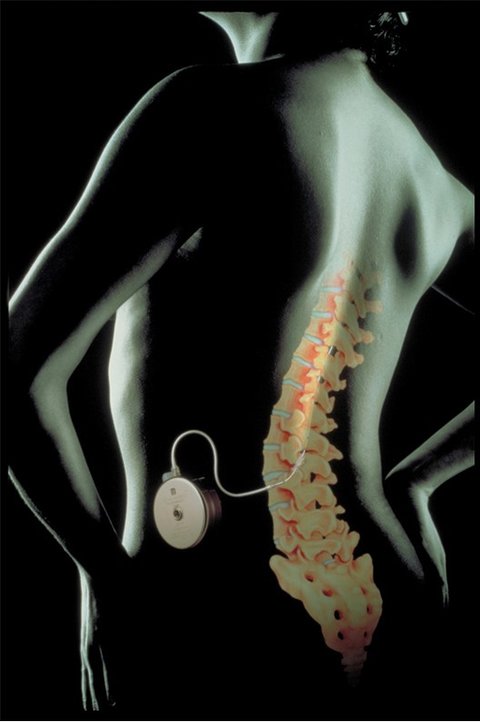

1. Drug pumps

Implanted drug pumps have to deliver continuously the correct dose of drug by using as little energy as possible. MPS miniature actuator technologies are biocompatible, efficient and designed for reliable long-term implantation.

MPS provide fully implanted solutions for the elongation of long bones (femur, tibia) and for the elongation of spinal rods used for the correction of scoliosis in children. Miniaturisation of powerful mechanics and electronics and mastering the use of biocompatible materials are the heart of such technologies.

3. Urology

Miniaturised biocompatible actuators developed by MPS are implanted provide the necessary power to close and open the urethra in person suffering of severe incontinence and though improve their quality of life significantly.

4. Heart surgery

MPS experience in heart surgery goes from the manufacturing of pump systems for artificial hearts to the development of miniaturised electro-mechanical systems meant to assist the heart function and to adjustable heart valves.

Micro robotics

Minimal invasive surgery, precision of delicate operation procedures…all of it need miniaturised, reliable, accurate electro-mechanical systems, the core know-how of MPS. Remarkable example of MPS expertise in the field of micro robotics is the worldwide smallest hexapod robot used for spine surgery. This device is currently manufactured by MPS.

Ophthalmology

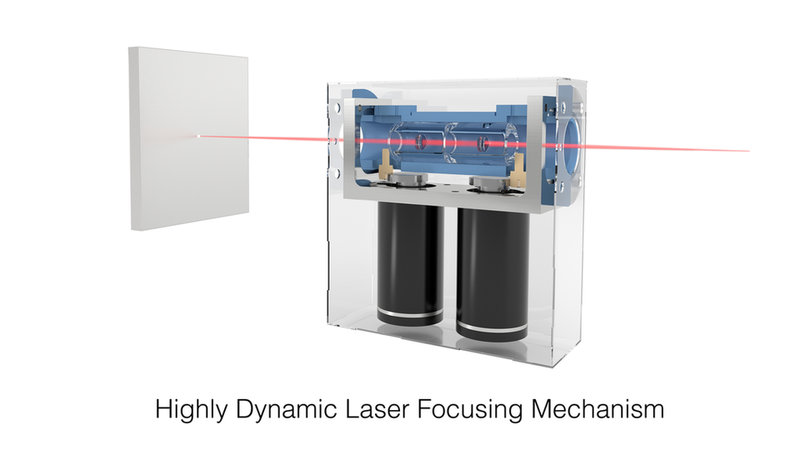

MPS provides miniature focus mechanisms with precision and position repeatability in the order of 1 micron. Such mechanisms are used to focus lasers during cataract and refractive surgery or during eye scanning.

MPS has developed an innovative and highly dynamic laser focusing mechanism. It is easily scalable with two linear ball bearings that match together in order to have an identical inside diameter.

Endoscopy

Today endoscopy devices are equipped with fixed lenses. In the future, optics with adjustable lenses will be used in order to improve image quality and handling by the surgeon. MPS provide miniature solutions for active optics in endoscope.

Camera based stereoscopic surgical imaging

MPS has developed a miniature scalable stereoscopic zoom mechanisms capable of fulfilling the requirement of camera based imaging in surgical procedures. The system allows perfect alignment and positioning of all groups of lenses inside the device and though generates focused images at any time.

MPS Microsystems develops and manufactures high-precision, high-performance and very low-friction electro-mechanical microsystems. Managing the miniaturisation and integration of functions in small spaces, MPS Microsystems provides solutions that meet specific customer requirements. MPS Microsystems also offers a standard range of products, such as linear bearings and ball screws under the “microlinea” trademark.

Located in Bienne, Switzerland, in a modern and well equipped facility MPS Microsystems offers its 220 employees an exceptional working environment and provides customers with unique capabilities that are perfectly suited to the requirements of the medical and high-tech sectors.

MPS belongs to the FAULHABER GROUP, the German manufacturer of micromotors.