Contact us for a quote or demo:

Web: www.Mecmesin.com

Phone: +44 (0) 1403 799979

Email: info@mecmesin.com

Your Partner for Force, Materials and Torque Testing Equipment

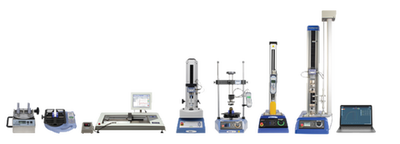

Mecmesin, established in 1977, is a leading designer and manufacturer of compression testers, tensile testers, universal testing machines and torque measuring equipment. We offer a full range of precision test systems and instruments that are accurate, reliable and excellent value for money.

Operating under ISO 9001 quality standards, Mecmesin test solutions are helping in the global fight against COVID-19, and used to guarantee the quality of components, materials and finished products, from factory floor through to the R&D laboratory – across all medical technology industries.

Our service is backed up by IQ, OQ and PQ document templates to support you in your process validation activities.

VectorProTM software is designed to help facilitate meeting FDA 21 CFR Part 11 requirements, with its database architecture and strict operator permissions features. For MDR regulations, barcode reader input scans the UDI of a medical device and reports this alongside its test results.

Our products enable you to perform checks to ensure:

- Conformance to standards

- Optimised design

- Efficient production

- Minimum wastage

- Cost savings

- Quality

Find out more about our medical industry test applications in:

- Medical devices and aids

- Connectors and components

- Packaging systems

Dedicated test systems for specific industries

Our software shows clear results of your test

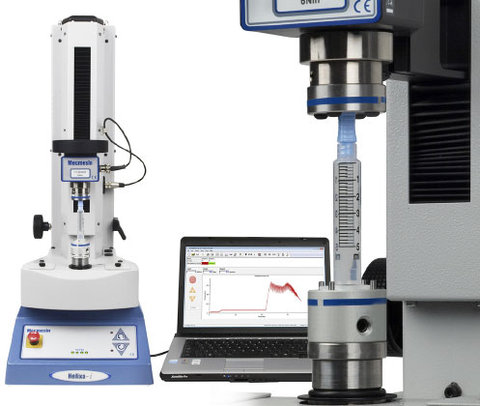

Precision equipment for delicate products

Accessories designed to test medical devices

Repeatable and accurate testing for R&D

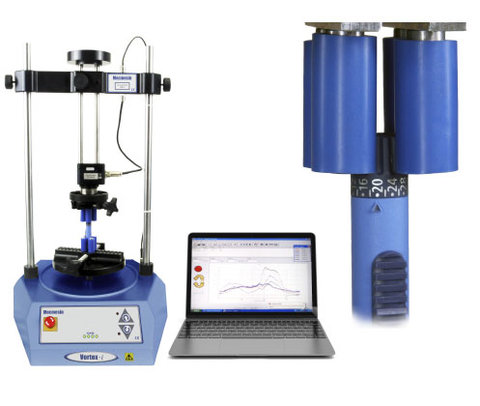

Torque testing solutions for the pharma lab

Watch our Automated Syringe Testing video

scroll down

Medical devices testing

Quality and reliability is key in a highly regulated environment, where patient safety is critical.

Operational, assembly, removal, and disassembly efforts can all be measured to protect and enhance brand reputation:

- Strength testing of PPE

- Integrity of ventilator components

- Vaccine delivery device testing

- Syringe glide effort

- Syringe pump calibration force

- Biopsy sample gun trigger force

- Drug delivery dial precision torque

- Insulin pen functional performance

- Inhaler disassembly resistance

- Ophthalmic adaptive lens adjustment effort

Mecmesin’s MultiTest equipment securely clamps these medical devices for repeatable tension and compression testing whilst our loadcells accurately measure the wide range of loads involved.

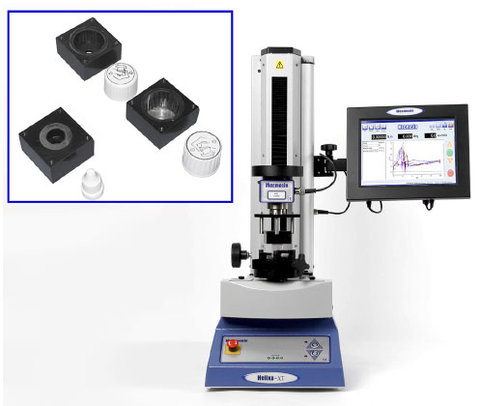

Very small torque values are detected and precise alignment is guaranteed with our Helixa torque testing systems.

For all testers our barcode scanning feature automatically assigns the Unique Device Identifier to the test results for MDR compliant testing.

Inhaler dissassembly resistance

MDR Barcode scanning assigns result to UPI

Insulin pen functionality testing

Touch-screen controlled tester for manufacturing QA

Lens adjustment dial ease-of-use

Biopsy injector trigger force test

Syringe glide force, assembly and calibration

Rotational effort for dosage pen

Vaccine delivery device test solutions

PPE strength testing

scroll down

Connector and component testing

The physical strength of connectors and key components in medical assemblies can be tested for reliability in use.

Measurement of the efforts to assemble or disassemble a medical device, or test its resistance to breakage, requires suitable test equipment and correct gripping fixtures:

- Luer design taper connector torque

- Tubing pull-out resistance

- Needle strength, bend resistance

- Needle lancet retention

- Stent disassembly resistance

Our range of OmniTestTM Universal Testing Machines enable the raw materials for packaging, products and components to be accurately characterised in tension and compression, from 2 N right up to 50 kN.

Mecmesin’s VectorProTM software is designed to help facilitate meeting the requirements of FDA 21 CFR Part 11, with its database architecture, operator permissions and audit-trail features. Extensometer connectivity and a comprehensive suite of materials testing calculations are included:

- Ultimate tensile strength (UTS)

- Stress and strain at break

- Young’s Modulus

- Yield and 0.2% offset yield

- 3 and 4-point flexural modulus

Luer connector assembly torque to turn

Stent connector and wire strength testing

Measuring the force to pull out components

Universal Testing Machine for material properties testing

Accessories for accurate strain measurement

Packaging systems testing

If you manufacture or supply primary, secondary or tertiary (transit) packaging, you need accurate and reliable testing systems to follow the stringent standards in force within the industry:

- Openability - peel and tear - of sterile packaging

- Puncture resistance of sharps containers

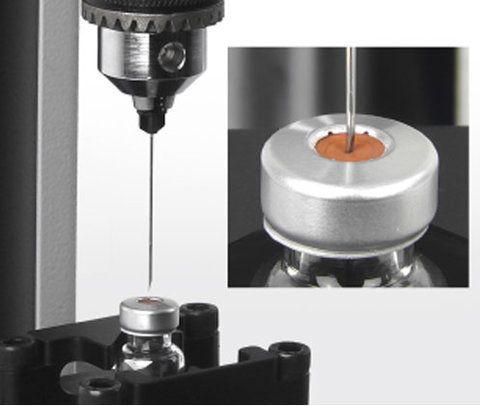

- Penetration of elastomeric closures

- Actuation force of pump and spray dispensers

Torque testing involves a range of tests designed for threaded closures. This includes measuring the torque to remove or apply the closure and also the measurement of the effort required to overcome critical safety features:

- Child-Resistant Closures (CRC)

- Evaluate push and twist designs

- Breach tamper-evident features

Mecmesin’s versatile motorised testing equipment ensures constant rotational speed control. This is essential for delivering far superior repeatability and accuracy compared to manual torque testers.

A comprehensive range of fixtures hold flexible specimens in a uniform manner without affecting the test results.

Transit packaging box crush test

Actuation force of a pump dispenser

USP testing of elastomeric closure

Highly accurate sterile packaging peel testing

T-Peel testing for industry standard packaging

Sharps bin material penetration resistance

Motorised, manual and custom closure torque solutions

Custom cap mandrels for the CRC manufacturer design

Child Resistant Closures need specialised testers

Personal Protective Equipment (PPE) Testing

Now, more than ever, meeting quality standards are key in the manufacture of personal protective equipment. However, the increased demand for PPE are pushing manufacturers to grow manufacturing capacity and expand some of their product lines at a very rapid rate.

We want to stand with you as you work to meet these demands and help to safeguard the lives of our nurses, carers, doctors, patients and the general public. Mecmesin’ s range of force and materials testing equipment will help you ensure your PPE meets quality-control standards - every single time.

PPE testing in action

Face Shields are a vital PPE tool being used by front-line workers in the healthcare sector to help prevent the spread of COVID-19.

Bloc Blinds, a leading UK manufacturer of roller blinds, is helping meet the surge in demand for PPE equipment by repurposing production facilities to produce self-assembly face shields. The Bloc FaceShield is a clear lightweight visor fitted with a foam forehead band.

The company wanted to make sure that the peel adhesive properties of the sticky tape were strong enough that the foam would not become detached as the wearer went about their duties, often subject to heat and perspiration.

Read this case study to see how Mecmesin helped them.

Tests designed for the PPE manufacturing community

Peel test on visor/face shield foam

Mask elastic band strength

Strength of mask connection to headband

Tear properties of PPE materials

Peel testing of sterile packaging

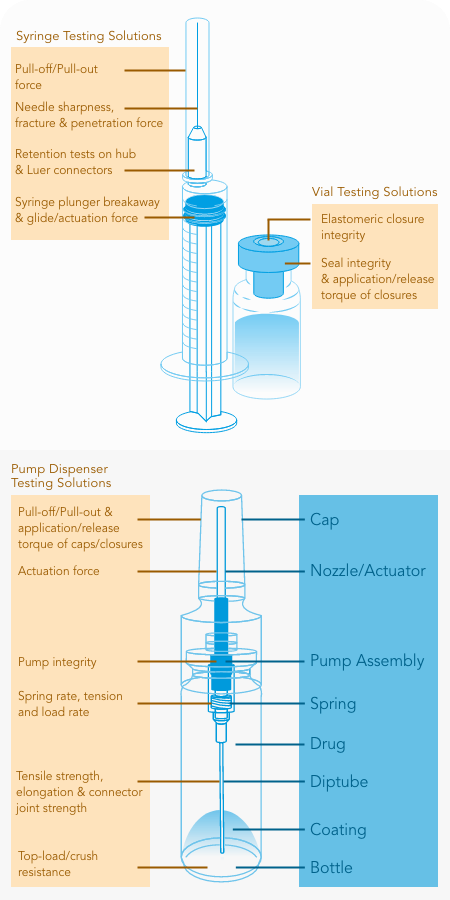

Download our latest Syringe & Vial whitepaper for free

In this whitepaper we provide you with an overview of the force and torque testing methods used to assess the quality and performance of syringes – from individual components through to the assembled device.

Also covered is the testing of the sterile medical packaging in which syringes are delivered and testing of the vial from which a syringe must extract and deliver the medication.

Contact us for a quote or demo:

Web: www.Mecmesin.com

Phone: +44 (0) 1403 799979

Email: info@mecmesin.com