Maximum productivity and accuracy are critical success factors in Medical Devices development, manufacturing and quality control. However, you need to be completely confident that you can trust your results all the way through your manufacturing process.

Let Sartorius save you time and increase your throughput by helping you control the quality of your Medical Devices, to produce results you can really rely on.

Introducing our customized solutions into your Medical Devices manufacturing and QC processes will not only improve your productivity, but also ensure full compliance to the most rigorous standards and requirements. Sartorius solutions enable you to streamline time-consuming, labor-intensive and potentially error-prone manufacturing processes, as well as quality control your workflows.

Download a brochure

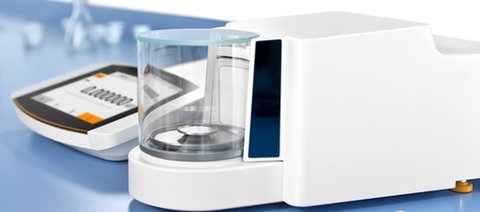

Peak performance weighing and back-weighing solutions for drug substances and excipients, as well as controlling the amount of coating on drug eluting stents – makes Sartorius Cubis® balances the perfect choice for stent manufacturers in the Medical Devices industry.

Even for tiny amounts of drug substances, Cubis® balances ensure high throughput, boosting your productivity via fast stabilization times, regardless of the stent size or weighing conditions you’re using. You can rely on precise weighing results and high-speed processing of all critical parameters.

Thanks to their flexible, seamless connectivity, Cubis® balances are easily integrated into any process and (ERP) system. Additionally, Cubis Q-Apps software offers you a range of options to use balance and process weighing data even more efficiently. And if your stent manufacturing and quality control processes have to fulfil specific criteria, we can customize our Sartorius weighing solutions to match your needs.

Discover Cubis® – the right balance between precision and productivity

Discover Cubis®

Quality Control of Drug Eluting Stents by HPLC requires robust, reliable sample preparation and streamlined workflows to ensure you get clean, reproducible, interference-free results. Sartorius supports you with simple, time-saving solutions for preparing your HPLC samples, as well as analyzing the content and purity of drug substances and excipients such as polymers for stents. This means your fully validated sample processing procedures can perform with robustness and reliability.

Small improvements from quality product selection can produce a significant impact on testing and is the simplest way to create the best results.

Check out the straightforward steps and optimized solutions to help you achieve accurate, reproducible results:

- Preparation of Buffers and Dilution of Samples

- Preparation of standards

- Accurate Pipetting

- Reliable Filtration

Discover Now!

Medical devices can improve the quality and even extend a patient’s life. In an increasingly complex regulatory landscape, continuous microbiological testing during manufacturing is crucial to ensure consistent, reliable product quality and more importantly, patient safety. With our established expertise in microbiological quality control, Sartorius enables you to achieve accurate, reproducible results for in-process and final release microbiological testing. We provide medical device manufacturers with fully compliant membrane filtration solutions, ideal for use in water, bioburden and sterility testing, as well as active air monitoring for clean room and production environments.

Check out how we can help you meet regulatory requirements in your microbiological testing:

Air Monitoring solutions

- Discover Continuous Active Air Monitoring solutions for Clean Room environments and be prepared for Annex 1 regulations.

Water and bioburden testing solutions

- Streamline your workflows and simplify your microbiological testing with user-friendly Sartorius consumables and equipment for microbial enumeration.

Discover Now!