COMPANY

INSIGHT

The company provides a wide range of production automation solutions, including customized systems designed to meet client requirements.

Ginolis holds patents for dispensing, micro-fabrication and precision robotics.

MICRO ASSEMBLY AUTOMATION

Ginolis is experienced in the assembly and production of micro medical components, rapid tests, point-of-care diagnostics devices, insulin pumps and test cartridges. All its automated solutions utilize machine-vision technology to ensure high-quality assurance.

The Ginolis Lateral Flow Device Assembly (LFDA) is a great example of the company’s innovative approach to automation. The LFDA provides rapid test manufacturers flexible production capacity on a compact scale, assembling multiple types of devices on one system with minimal adjustments. The system’s modular design makes it easy to integrate cells for additional processes such as pouching, kitting, ultrasonic welding, laser marking, labelling and RFID tags.

Ginolis automation solutions are compact, saving companies valuable space in clean room environments.

LOW VOLUME PRECISION DISPENSING EQUIPMENT

Ginolis’ high-precision, non-contact dispensing solutions range from standard pumps and dispensing platforms to fully customised systems.

The company’s innovative solutions utilize its robotics platforms and patented Piezo Motor Bellows (PMB) pump technologies to provide high-precision nanolitre dispensing, microarray spotting, pipetting and surface treatment applications.

Ginolis’ dispensers include an integrated pressure sensor for clog and leak detection, automated monitoring of pressure stabilisation during pre-dispensing, air in fluid detection and pump pre-pressurising. This system is low maintenance and has a long service life.

Ginolis dispensing solutions utilize the company's modular automation platforms and PMB pump technology.

3D METROLOGY AND QUALITY INSPECTION FOR PRODUCTION AUTOMATION

Ginolis’ quality inspection solutions provide production speed measurement and analysis of all materials and surfaces. Inline and stand-alone solutions are able to analyse a wide range of materials, including various shapes and colours, as well as surface types such as glossy, matte, mirror-like and transparent.

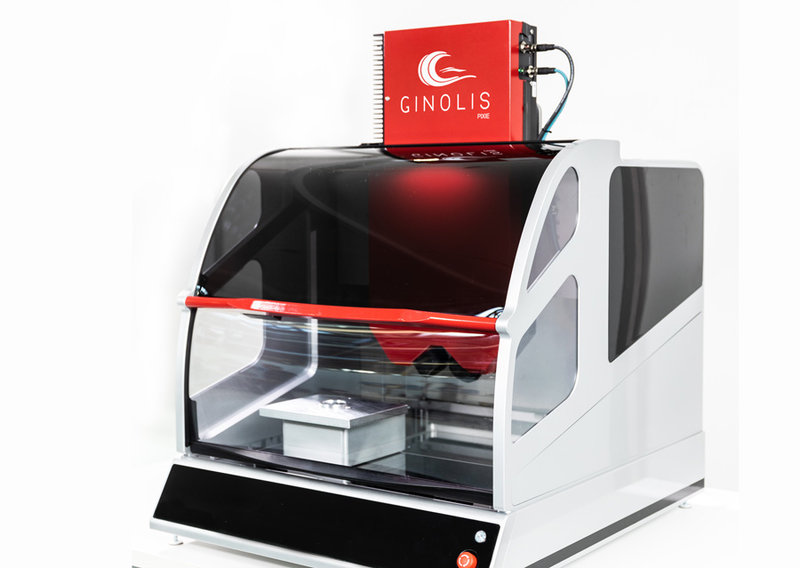

Ginolis Pixie platform provides high speed quality inspection of all materials and surfaces..

MODULAR DESKTOP AUTOMATION

Ginolis’ modular and desktop automation solutions are smaller compared to traditional units, saving companies valuable space in cleanroom environments.

Its highly robust robot modules provide consistent production quality in a highly regulated industry. The modular approach and application-specific products reduce lead-times for delivery of customer solutions. Ginolis also provides production equipment validation support.

PRECISION FOR WELL-BEING

Ginolis’ vision is to improve the well-being of people by creating innovative automation solutions for precision liquid handling and micro assembly to ensure high product quality in the medical device industry.

ABOUT GINOLIS

Established in 2010, Ginolis set out to provide cutting-edge innovative automation solutions for the diagnostic and medical device industries. The company's founders, who have an extensive history in the development of assembly automation for the consumer electronics industry, wanted to bring that unique know-how and technology to the medical device and diagnostic industries.

The company is headquartered in Oulu, Finland with offices and distributors located globally. Ginolis is privileged to work in co-operation with many of the world’s leading diagnostic companies.