COMPANY

INSIGHT

GF Machining Solutions

drives innovation in manufacturing

From the first EDM machine in 1955 to the five-axis high-speed Milling systems of today, GF Machining Solutions remains a manufacturing technology pioneer, providing the highest quality machines coupled with truly innovative solutions.

Our brands include AgieCharmilles, Microlution, Mikron Mill, Liechti, Step-Tec, and System 3R and, together, we deliver complete, efficient solutions to meet your product manufacturing needs. Backed by our own research and collaborative projects with specialized universities, our solutions deliver surface quality unmarred by the manufacturing process and completely compatible with medical and dental industry standards.

Innovation, precision, productivity and service are the hallmarks of GF Machining Solutions. As a world leader in multi-technology machining solutions, we are a preferred partner to leading medical manufacturers.

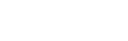

From 3D Direct Metal Printing solutions and Laser texturing to Milling, Electrical Discharge Machining (EDM), Tooling and Automation, our technologies can help you drive product innovation by enabling you to create products that provide unique value for patients, reduce your manufacturing risk, improve your efficiency and differentiate you from the competition.

www.gfms.com/com/en/Products/industrial-segments/medical.html

GF Machining Solutions keeps your operation healthy by delivering the innovation, precision, productivity and service you require in the manufacturing of high-quality tools and parts for the medical and dental industries. For many years, GF Machining Solutions has been actively involved in the medical sector, offering the best technologies associated with a wide range of manufacturing processes.

We understand your need for traceability of materials and real-time monitoring to secure your processes and keep you on top of stringent regulations, as well as superior process performance in terms of accuracy, flexibility, high productivity and low running cost. We go a step further by developing our solutions in alignment with your manufacturing needs, keeping in mind your needs regarding time to market, repeatable quality, and experience.

Direct Metal Printing

Our partnership with 3D Systems has helped to take Additive Manufacturing technology from the research lab to the factory floor. With our DMP Factory 500, we provide a turnkey solution that includes direct metal 3D printing, powder management, market-leading software, and a wide range of raw materials—all supported by technical experts who help take your project from concept to reality. With this optimized solution allowing for seamless transition between additive and subtractive manufacturing, manufacturers achieve greater efficiency via workflows for advanced metal manufacturing. The DMP Factory 500 drives efficient management of post-processing steps—such as Milling and wire-cutting EDM—alongside users’ metal additive production processes.

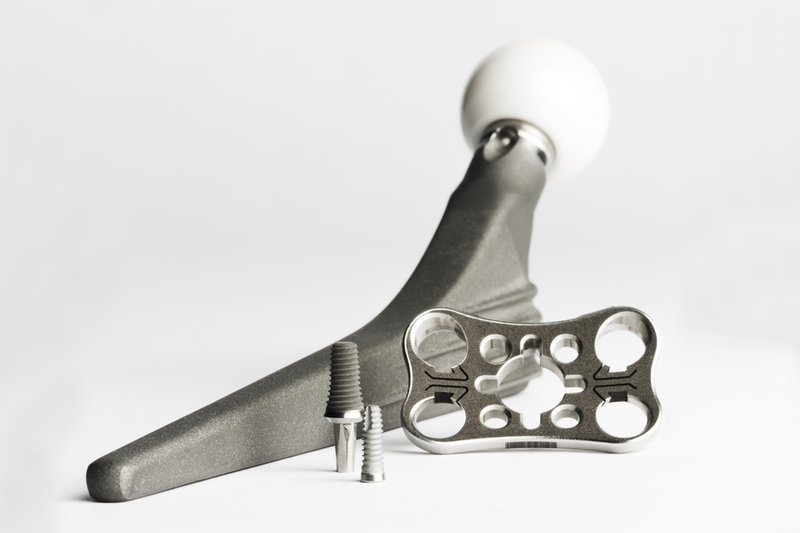

Laser texturing

Our Laser texturing systems allow our customers to replace grit blasting and acid etching with a clean, digital process that is fully repeatable. With easy-to-use software and unbeatable performance, our customers can map their own textures and structures onto complex 3D surfaces or use our standard patterns to create the surface characteristics needed to take device functionality to the next level. Our Laser texturing solutions perfectly fit injection molding applications for engravings on molds for consumables and medical packaging. In the future, more device manufacturers will use Laser texturing to improve connective tissue growth and to create microscopic drug delivery reservoirs, for example.

eTracking

eTracking provides real-time monitoring of critical quality parameters during EDM operations, taking the control of this process and product quality to the next level. With up to 50 different data points measured and stored every second, users receive a log file that provides documented confirmation of the manufacturing process. With eTracking connecting GF Machining Solutions machines and providing parametric feedback, manufacturers can achieve unprecedented process optimization.

Automation

Our production-optimizing Automation cells are adaptable and fully compatible with our entire range of machining solutions. They are superbly integrable in your existing production environment and deliver increased process control, greater efficiency and faster time to market. Our vast global experience in developing automated solutions for medical manufacturers positions us to help you standardize your processes and significantly reduce the number of steps required to achieve your production targets.

Our high-quality, integrated Automation cells help you control production quality and costs and keep the work process clean and efficient, all must-have conditions for medtech manufacturing.

Passion for Precision

Whether your products are injection molds for medical consumables, artificial hips, or dental implants and superstructures, GF Machining Solutions offers market-leading technologies that help you provide best-in-class solutions to your customers. With our headquarters in Switzerland and a presence in 50 countries, we support medical device manufacturers worldwide.

Products

Look to GF Machining Solutions for machine tools for Milling, EDM, and Laser machining, as well as systems for Direct Metal Printing, Laser texturing and factory Automation—all available with Industry 4.0 technology.

3255 employees, CHF 992 million sales in 2017