Picosun provides the leading

THIN FILM COATING SOLUTIONS

for medical industries

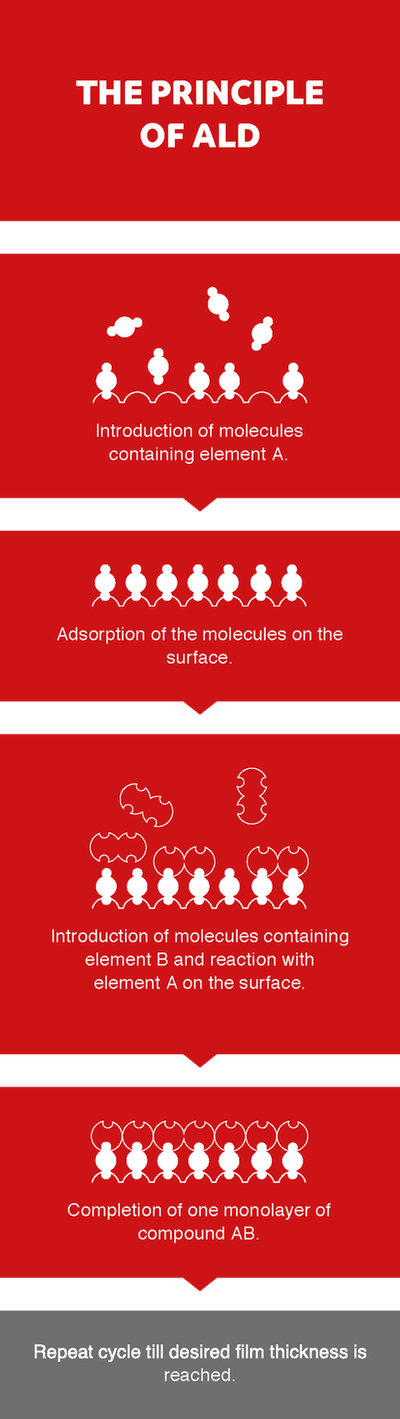

Picosun is the leading provider of AGILE ALD® (Atomic Layer Deposition) thin film coating technology for healthcare industries.

Picosun’s biocompatible ALD coatings enable safer and longer lasting products, more compact sensing, therapeutic, and analysis devices, and novel medical applications such as microimplants, smart ablation catheters and deep brain stimulation probes.

Picosun’s PicoMEDICAL™ ALD solutions are already in production use in healthcare industries in depositing bioactive coatings on surgical implants and functionalizing the surface of drug particles for controlled drug delivery.

Application examples:

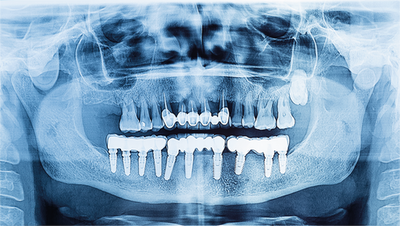

Dental and orthopedic implants, surgical fixators

• Improved osteointegration with bioactive TiO2 thin films

• Biobarriers for encapsulation against metal ion leakage into tissue fluid

Read more

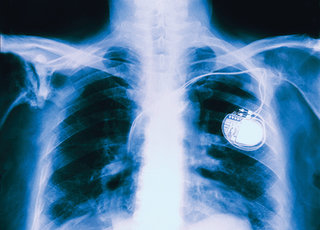

Pacemakers and other implantable electronic devices, microimplants

- Hermetic biobarrier encapsulation of the device electronics against the effect of tissue fluid

Read more

Others

- Medical MEMS, sensors, and Lab-on-a-Chip devices

- Controlled/targeted drug delivery

- Hydrophobic/hydrophilic coatings

- Functional coatings on powder materials

- Extremely thin films on stents

BIOACTIVE ALD THIN FILM COATING SOLUTIONS

for surface treatment of metal implants

Medical implants and implantable devices often need to be sealed against corrosion caused by body fluids, and also the body needs to be protected from inflammatory and rejection reactions and possible metal ion leakage caused by the implant.

Biocompatible ALD thin film encapsulation provides reliable, hermetic sealing of dental/orthopedic implants and other stainless steel or titanium items.

- In titanium-based dental implants the implant surface functionalization with bioactive ALD TiO2 coating accelerates the osteointegration process(*). ALD TiO2 has excellent adhesion also to the implant material, resulting in tighter bond between the implant and the bone.

- The excellent uniformity, conformality, and pinhole-free quality of the ALD films ensure that the desired film function can be achieved with extremely low film thicknesses, leading to material and cost savings.

- With ALD, risks for microscopic surface damage, often present with other coating methods, and which can be problematic regarding the aseptic requirements and long-term stability of the coating, can be prevented.

- Several ALD film materials are intrinsically biocompatible/bioactive. Al2O3, TiO2, HfO2, SiO2, ZrO2, Nb2O5, Ta2O5, AlN and TiN ALD films manufactured by Picosun have been tested and validated by an independent third party to be non-cytotoxic and safe to human tissues in e.g. implant applications(**).

- Picosun offers production-proven ALD processes for various biocompatible/bioactive oxide materials such as TiO2.

- High throughput, cost-efficient surface treatment of thousands/tens of thousands of implants per run is realized in Picosun’s large scale batch ALD reactors.

(*)B.S. Smbatyan et. al., Rossiyskaya Stomatologiya 4, p. 15-24, 2014.

(**)FICAM – The Faculty of Medicine and Health Technology, University of Tampere, Finland: Cytotoxicity tests with cell culture medium according to the ISO 10993-5 standard, and 3 weeks soaking tests in PBS (phosphate-buffered saline) at 87 oC.

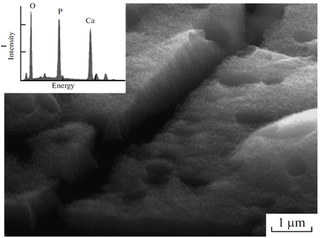

SEM picture and EPMA analyses of Ti plates with anatase TiO2 coating, after soaking in simulated body fluid (SBF) for 6 days(***).

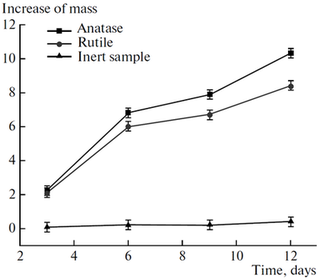

Comparison of hydroxyapatite formation on plain and ALD TiO2 coated Ti samples in SBF(***).

(***)A.A. Solovyev et. al., Nanotechnologies in Russia 8, Nos. 5-6, p. 388-391, 2013.

BIOCOMPATIBLE ALD THINFILM COATING

SOLUTIONS for microimplant encapsulation

Remote sensing and therapeutics through self-powered, wirelessly operating microimplants is an emerging technology in e.g. neural stimulation and diagnostics, and in blood glucose, blood pressure, intraocular and intracranial pressure measurements.

Hermetic encapsulation of the implants is required to protect them from the corrosive effect of body fluids, and also to protect the body from the possible inflammatory or rejection reaction caused by the implant.

- ALD thin film encapsulation is an ideal method for reliable, hermetic sealing of various implantable devices.

- Picosun has developed a biocompatible ALD nanolaminate encapsulant that can potentially ensure microimplant lifetime of over 10 years in human body environment(*).

- The nanolaminate deposition process is readily scalable to high throughput, cost-efficient industrial production of thousands of implants per run in Picosun’s batch ALD reactors.

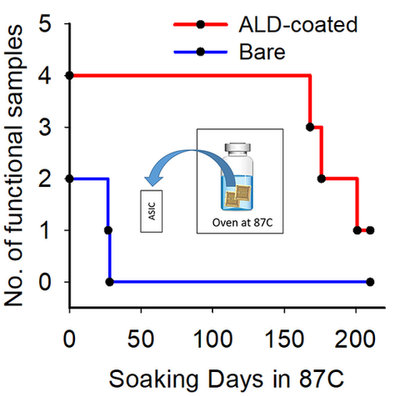

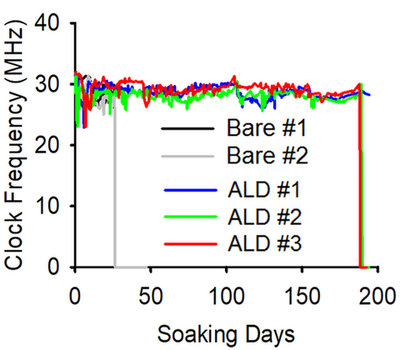

- The performance of the ALD nanolaminate encapsulants has been investigated in accelerated aging tests in 87 oC saline, comparing encapsulated and bare microelectronic chiplets for wireless body implants (tests performed at Brown University, USA).

- The chiplets stayed operational with no signs of degradation in the hot saline bath for over 180 days. This implies an equivalent lifetime of over 10 years in human body environment at 37 °C(**).

- High throughput, cost-efficient surface treatment of thousands/tens of thousands of implants per run is realized in Picosun’s large scale batch ALD reactors.

(*)J. Jeong et. al., Adv. Funct. Mater. 2018, 1806440.

(**)Standard accelerated lifetime extrapolations, based on the rates of chemical reactions doubling when the temperature is increase by ~10 degrees Celsius.

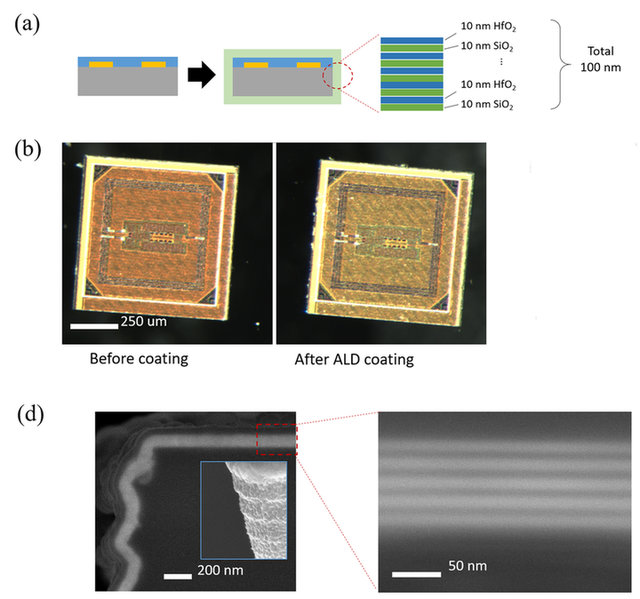

a) Schematic of Picosun’s ALD nanolaminate on ASIC microchiplets,

b) microscope images of the chiplets before and after ALD encapsulation,

d) SEM images showing conformal ALD coating around edges and corners of test silicon pieces(*).

Time-series plot showing functional microchiplet population versus the soaking test time in 87 °C saline for both ALD-encapsulated and bare chiplets.

On-board clock frequency of the chiplets versus the soaking test time in 87 °C saline. Analyzed from four ALD-encapsulated and two bare (as received from fab) microchiplets(*).

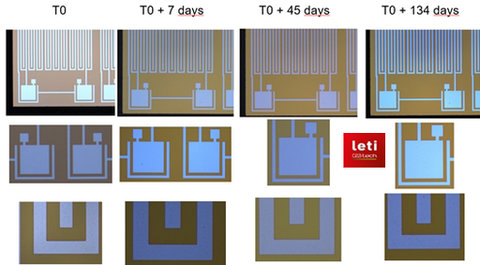

Microimplant electronics protected by Picosun’s ALD HfO2. No changes after soaking in 87 oC PBS for over 3 months which correlates to over 10 years in human body. T0 = starting point of the test. Reference: InForMed EU project, image source CEA-Leti.

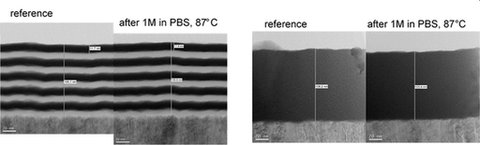

TEM micrographs of Picosun’s ALD nanolaminate and oxide encapsulants after one month soaking tests in 87 oC PBS. No corrosion observed.

PICOSUN AGILE ALD® SOLUTIONS FOR HEALTHCARE INDUSTRIES

Picosun’s comprehensive, turn-key ALD solutions enable novel, cutting-edge products and add value to existing ones in form of improved safety, lifetime, and comfort of use.

Our PicoMEDICAL™ solutions are tailored especially to the needs of healthcare industries who are often still new to ALD. They consist not only of the ALD equipment itself, but of optimized, production-proven processes, application and ramp-up consultancy, and the most extensive and versatile after-sales service and support packages to keep your production running flawlessly.

All of this is the result of our unmatched history and know-how in ALD. As the pioneers of the technology for over 40 years, we have all the knowledge and experience in the world when it comes to taking ALD to new frontiers to improve the quality of life for all of us.

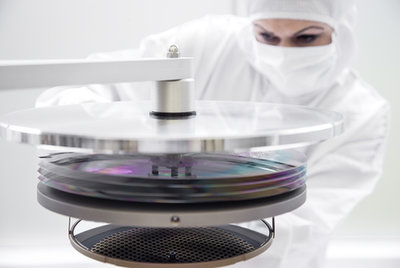

PICOSUN® ALD equipment

The PICOSUN® P-series ALD systems are the new standard in high volume ALD manufacturing. By integrating our patented hot-wall reaction chamber design with fully separated precursor chemical inlets, we can create the highest quality ALD films with excellent yield, low particle levels, and superior performance. The agile design with easy and fast maintenance ensures minimum system downtime and the lowest cost-of-ownership. Our proprietary Picoflow™ diffusion enhancer technology enables highly conformal coatings on the smallest nanoscale surface details, powders and particles, and ultra-high aspect ratio structures.

The PICOSUN® P-300B and P-1000 large-scale batch ALD systems are specially designed for coating surgical implants, implantable medical devices, microimplants, and medical MEMS, sensors, and Lab-on-a-Chip devices.