HIGH-PRECISION CNC TURNED AND MILLED PARTS

KSP stands for design, service and production.

We support you through every step of the process: from the initial idea right up to the production of your precision parts.

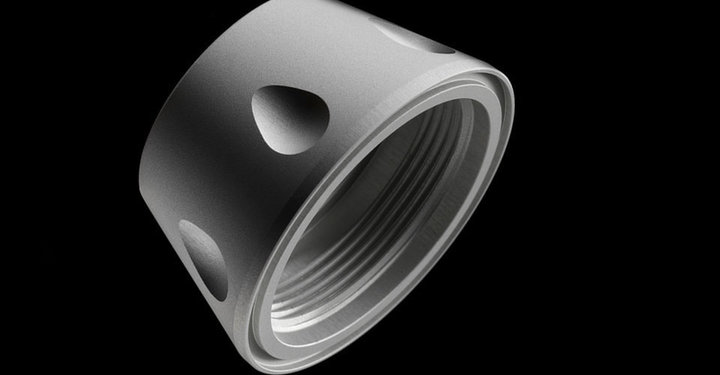

We use computer-controlled machines to produce high-quality turned and milled parts with complex geometries for many varied application areas especially in the medical technology field. Our focus is on the processing of materials which are difficult to machine.

OUR EXPERTISE AT A GLANCE

• Materials difficult to machine (titanium, titanium alloys, stainless steels, special alloys)

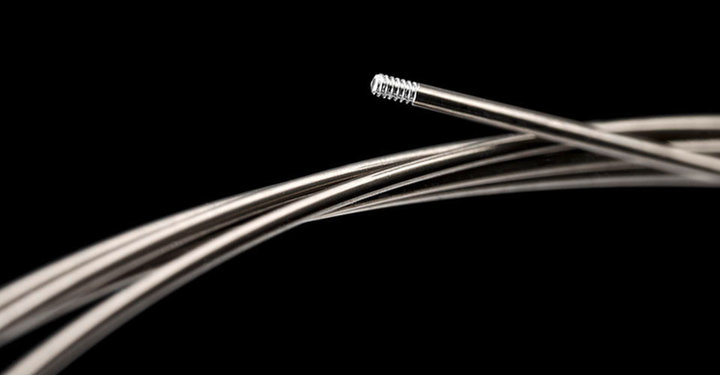

• Small(est) parts starting from Ø 0,65 mm up to Ø 42 mm in turning of bars, Ø 70 mm as chuck parts

• comprehensive machining (5 axes) and a milling range of 250 x 250 x 200 mm

• Complex geometries with very low tolerances

• Highest precision in μ-range (from 0,001 mm)

• Surface finishing: coating, polishing, blasting etc.

• Services: 3D-Printing, CAD drafting, clean-room services, laser marking, warehousing and indivual delivery concepts

HIGHEST QUALITY SYSTEM

KSP delivers high quality components according to

DIN EN ISO 13485: 2016

DIN EN ISO 14001: 2015

from high quality materials supplied by certified manufacturers or dealers in Europe. Our materials conform to EU directive 2011/65/EU (RoHS 2) and EU regulation no. 1907/2006 (REACH).

We feel at home wherever there is a need for our production engineering. Our team has many years of experience in many varied fields, especially in medical engineering. Specialists in these fields appreciate our demanding quality standards and high level of production expertise.

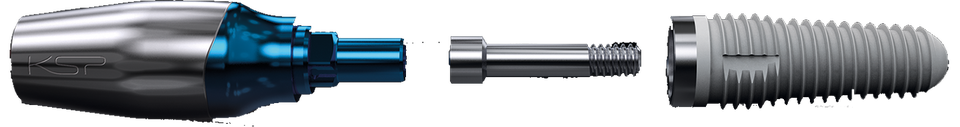

Using high precision engineering, we design and produce customised high quality, dental implants, abutments, instruments, orthopedic implants, spinal implants, cortical screws, housings, holders, connectig peaces or any other medical engineering parts and non-medical engineering parts, individually for you.

Close communication between customers and suppliers has frequently enabled us to use our production technology to establish a basis for innovative products and support you in the realisation of your development objectives.

IT’S ALL ABOUT SERVICE

Your satisfaction is our priority. We are happy to take care of all the required internal and external process steps and offer you a one-stop shop solution.

We work with all types of chemical, electroplating and finishing techniques such as anodising, functional layers, laser marking of parts and sterile packaging on a daily basis. In this process we work together with well-known specialists in the respective field.

CONTACT US

IN THE HEART OF THE HECKENGÄU REGION!

At the gates of Stuttgart – with the Black Forest nearby!

KSP Technologie GmbH

Josef-Beyerle-Straße 14

71263 Weil der Stadt

Germany

Phone: +49 7033 69203-0

Fax: +49 7033 69203-20

Email: info@ksp-cnc.de