COMPANY

INSIGHT

About Innomech

GB Innomech is recognised as one of the UK’s leading Automation specialists, applying their skills to both new, early stage businesses as well as some of the established FTSE 100 companies. Size is not important; but we take great pride in our ability to establish strong long term relationships at both the organisational and individual levels.

Established since 1990 and based in the award winning innovation centre, our carbon neutral offices and workshop, within the Cambridge technology cluster we work with companies worldwide to reduce cost and improve the quality of their products through automation. We work from providing feasibility studies to providing fully validated solutions. A strength, which often separates us from others, is that we can always make what we propose and design!

Our risk based approach, where we undertake risk assessments throughout the project, and where we solve the ‘real’ problems, which are often different to those first perceived, has led to a strong reputation for providing innovative solutions within regulated environments.

Innomech - Bespoke Automation Specialists

Innomech excels at designing, developing and producing innovative special purpose automation machines for the manufacturing industry. From prototypes, to bespoke automated equipment aimed at improving productivity, profitability and compliance.

Cambridge UK based, with over 20 years’ experience in producing bespoke automated machines including, control systems, end of line testing workstations, dispensing and assembly machines to a range of industries including, medical device industry.

Innomech offers a committed team with experience in specialist technologies including, robot handling, PLC control, pick & place and vision systems, with skills in mechatronics, production automation and specialised automation control systems engineering, innovative bespoke design, and validation.

Medical Device Automation

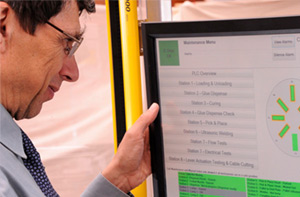

The medical division is headed by Dr Peter Woods – an acknowledged expert in automation in the pharmaceutical industry, with his vast experience in developing automated manufacturing systems for the assembly and test of medical devices.

Peter leads a multi-disciplinary team to design and build automation equipment for developers and manufacturers of products such as drug delivery pens, contact lenses, diagnostic kits and surgical instrumentation.

Innomech offers everything from feasibility studies through to large-scale system builds. Every system is developed in parallel with a detailed validation document package, including Installation and Operational Qualification (IQ/OQ), CFR21 part11 conformity, Gauge R&R and other relevant studies to enable fast and low cost regulatory compliance.

The company’s track record includes developing machinery for most of the world’s top pharmaceutical companies, as well as many early-stage technology businesses looking to bring first products to market.

Dr Peter Woods is head of medical device manufacturing at GB Innomech but has helped many global businesses to avoid the unnecessary costs and delays due to manufacturing issues in bringing new products to market.

Designing flexible automation

Most medical devices are assembled and tested using automated equipment, but it’s not unusual to need to specify and build the assembly equipment while the design of the device itself is still evolving. The problem for system developers is providing the necessary flexibility within the automation to accommodate these adaptations, while at the same time delivering the required control of process when the final medical device moves into production.

This dilemma is particularly relevant for medical device manufacturing because the possible impact on human health of a faulty assembly means that almost every step in assembly and testing must be shown to be operating correctly within a well-defined range of process parameters as part of a rigorous process of validation.

Medical Device Assembly

GB Innomech have experience in producing systems ranging from bench top measuring devices to fully automated medical device assembly and End Of Line Testing (EOLT) machines enjoying repeat custom from many of the most respected medical device manufacturers, as well as many early stage technology businesses looking to bring first products to market.

Our automated medical device assembly machines are designed around your production specifications and can consist of glue dispensing, UV curing, vision inspection for both component compliance and final assembly.

We can supply a fully validated machine, with full validation documentation based on the Gamp 5 model with full component traceability and CFR21 part 11 compliance. We can also provide full test documentation, including Installation and Operational Qualification (IQ/OQ) , Gauge R&R and other relevant studies.