COMPANY INSIGHT

Sponsored by Sandvik

The importance of choosing the right coating at design stage

In a webinar about coatings for medical wire components held in September by Sandvik Materials Technology’s medical unit a poll stated that 60% of the attendants responded that the most frequent design issue is to find the right coating.

M

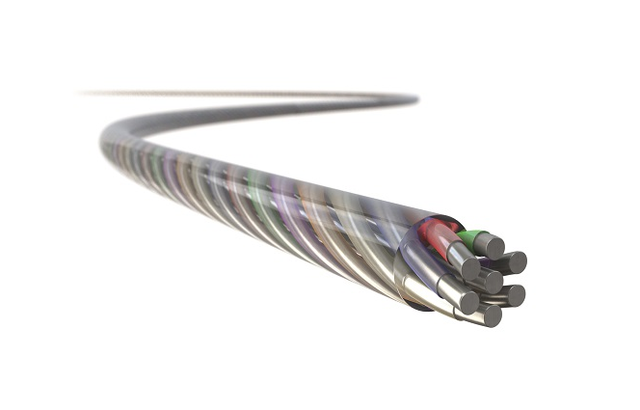

edical-wire components are an essential part of a number of therapeutic devices, from pacemakers to catheters to glucose monitors. They play the important role of transmitting, sensing or stimulating signals within the body, all the while needing to be biocompatible and offer various features (depending on the application) such as lubricity, conductivity or fatigue resistance.

In addition to choosing an appropriate metal material and configuration (such as thickness or coiling etc), manufacturers are also faced with the task of choosing what coating their wire-component requires to ensure the medical device is as efficient and reliable as it can be. This was presented in a webinar Sandvik Materials Technology conducted in September. A poll completed during the webinar also confirmed, “Coatings effect on wire-based components in medical devices”, is a significant challenge.

Viewers were asked “what are the most frequent issues in the design phase for you?”, 20% of respondents stated that their common issue was “to meet deadlines due to lack of resources, while a further 20% suggested a “lack of materials and coating knowledge in-house.” Notably, 60% of respondents said that the most frequent design issue for them was simply “to find the right coatings.”

Sandvik offers more than forty polymer-based stand-alone dip-coating options, which can be combined to formulate a custom-built solution.

With this in mind, the webinar presented and explained to viewers how product performance, manufacturability and cost are affected when it comes to coating selections. The speakers - Gary Davies, production and business unit manager at Sandvik Palm Coast, Gene Kleinschmit, senior product manager, and Josh Geitner, engineering and facilities manager shared their long and extensive experience in the field.

From the left; Gary Davies, Gene Kleinschmit, Josh Geitner

Finding the right coating is indeed a challenge, even for an experienced design team. There are numerous and ever-changing options on the market. Sandvik offers more than forty polymer-based stand-alone dip-coating options, which can be combined to formulate a custom-built solution. As the poll suggested, customers may be aware of the various options available, but they require the expertise to find the right solution based on experience and effective prototyping to keep within deadlines and prevent unnecessary expenditure. The goal for the webinar was to share the experience Sandvik has accumulated with those in the medical device industry who want to learn more about the key interactive parameters that help to drive a better product design decision and create reliable long-lasting products.

Polymer coatings are typically applied to wire-components for medical devices to provide electrical isolation for signal transmission, offer a lubricious surface layer to reduce tissue damage, or to enhance biocompatibility. Manufacturers must also keep follow-on procedures in mind, such as coiling and stranding, as this will affect which coating is optimal.

The webinar explained what coating methods are used and why. Multiple flood or dip processes are used to achieve process full coating thickness (which range from 0.005 mm to 0.05mm) and employing a multi-layered design will instill unique properties. They also discussed what polymer materials are available, including synthetic resin-based coatings, self-bond thermoplastics, and high-performance polymers, as well as explain the properties that different polymer materials provide and their suitability for different applications. Additionally, the webinar also discussed the key areas of consideration that occur during the selection process, including material formability, abrasion resistance, adhesion, solvent resistance, thermal stability, colour and biocompatibility, as well as cost and coating removal methods.

You can still listen in to the Sandvik webinar here to find out how to select the optimal coating for medical device wire-based components.

Contact information

Sandvik Palm Coast

1 Commerce Blvd.,

Palm Coast, FL, 32164,

United States

Website:exera.sandvik

E-mail:ms.spc@sandvik.com

Telephone: +1 386 445-2000

Fax: +1 386 447-5113