Dimensional metrology to increase safety of medical devices, implants and pharmaceutics

High-resolution optical 3D metrology is indispensable in the manufacture and quality assurance process of instruments, implants and other medical devices.

With only one sensor, dimension, position, shape & roughness can be measured.

Optical 3D metrology measures:

- non-destructive

- traceable

- smooth + highly polished surfaces

Check out the following material to find out more details on optical 3D measurement solutions used in all stages of the manufacturing process of medical devices

Measurement Report | High-gloss Knee Implant

Quality Assurance of Orthopedic Implants

The highest possible precision is the top priority in the manufacture of orthopedic and traumatological implants of all kinds. Modern implants usually have complex geometries with steep flanks and sometimes high-gloss surfaces, which increasingly presents manufacturers with challenges in production and the necessary quality assurance. This is exactly where optical 3D measurement technology comes in as a quality assurance instrumentl.

DOWNLOAD REPORT

Webinar | Quality Assurance in Medical Technology

Measurement of Surgical Instruments and Implants

In this webinar you will learn more about high-resolution form and roughness measurement of surgical instruments like drills and cutters, implants and other medical devices.

WATCH WEBINAR

User Case Story | Uhlmann

Optical Metrology in Pharmaceutical Packaging

Product safety is particularly important in the production of pharmaceutical packaging and is subject to stringent requirements. UHLMANN – a German expert in the field of pharmaceutical packaging – use Bruker Alicona to verify the quality of machine components, thus gaining knowledge on the reproducibility of manufacturing processes.

READ USER CASE

Online Demo: Let’s discuss your application virtually!

Book your live online demo with our experts.

BOOK YOUR DEMO

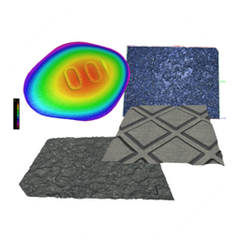

Dimensional metrology and surface roughness measurement

We are a global provider of optical, industrial measurement technology for quality assurance of complex components of different shapes, sizes and materials.

Based on the technology of Focus-Variation, our measuring systems close the gap between classical dimensional metrology and surface roughness measurement

With one system it is possible to measure:

✓ Dimension

✓ Position

✓ Shape

✓ Roughness

Dr. Auner Straße 21a

8074 Raaba/Graz, Austria

Phone: +43 316 403010 700

Fax: +43 316 403010 711

E-mail: sales.alicona@bruker.com