COMPANY INSIGHT

Sponsored by BioInteractions

BioInteractions innovates and manufactures high-performance, multi-action coating technologies.

Our multi-action coatings include Astute® Antithrombogenic Coating, AvertPlus™ Antimicrobial Coating and Assist™ Lubricious Coating. BioInteractions have innovated a broad portfolio of multi-action coatings to enhance surface performance. This broad portfolio gives us significant expertise and advantage when tackling the complex challenges surfaces are faced with.

M

ulti-action coatings confront complex challenges seen by medical device surfaces, with high-performance, multi-phased coating solutions. Multi-action coatings consider the various challenges faced by a surface and tackles them in one straightforward, high-performance coating. Our multi-action coating technologies provides market leading performance, long-term stability on a broad range of surfaces, is non-leaching and performs without using toxic chemicals.

We support our multi-action coatings with our customer centred, Commitment to Care (C2C) support services. Our C2C services enable us to address a wide range of surface challenges on a variety of devices and allowed us to develop a significant amount of expertise in applying our multi-action coatings on a variety of shapes and substrates.

These coatings feature on a range of commercialised products and have received either a CE marking or approval from the US Food and Drug Administration (FDA). Multi-action coatings are suitable for a variety of applications, materials, and surfaces. Our project history includes a variety of products used in diverse market which range from highly specific medical devices to everyday items.

BioInteractions are the all-in-one coating partner with our innovative, multi-action coating technology and customer focused C2C support services. Our multi-action coatings have a significant history of enhancing device performance and maintained our partners’ market share. Our C2C support services are a range of customer focused facilities to help streamline development efforts and further enhance device performance.

Commitment to Care (C2C) Support Services

BioInteractions’ C2C support services allow us to use over 25 years of expertise and enhance our partners’ development process. We have paired our multi-action coatings with customer focused support services to your all-in-one, coating partner. Our C2C support includes a tailored application process for each device, our coating performance tests, and our in-house coating services.

Our C2C service begins with our in-house testing services, which have been developed to measure the beneficial effects of our multi-action coatings. The testing helps to improve our partners’ understanding in their coated device to support their regulatory submission packages.

Our C2C service also includes tailored application process for each specific product to improve stability and performance of the coating. An optimised application process ensures a variety of shapes, materials and surfaces gain value from our multi-action coatings.

Our C2C service is completed by our in-house coating service. Our partners can gain benefits from our experience and have their final, commercial devices coated in our controlled facilities. Our in-house coating service helps to improve the quality and reliability of the coated device. This ensures our partners are receiving a consistent, high-quality coated device and as reduced concerns of replicating the coating process in another facility.

Our high-performance, multi-action coatings and customer focused C2C services are combined to be your all-in-one, coating partner. A partnership with BioInteractions’ multi-action coating technology and customer focused C2C services enhances your device performance, helps streamline your development process and improves the quality of your final coated device.

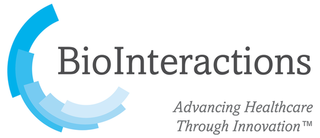

Astute® Antithrombogenic Coating

Astute Antithrombogenic Coating uses multi-action technology to prevent thrombosis formation, mimic endothelia action and reduce deposition onto the surface. The coating uses an active antithrombogenic agent and combined this with additional passive elements to provide a high-performance, non-leaching antithrombogenic coating.

The active agent actively stops blood activation and prevents thrombus from forming. Blocking the activation of blood prevents a thrombus forming downstream and reduces risks to the patient. The passive elements prevent platelet adhesion and deposition of blood components onto the surface. These additional elements protect the surface from interacting with blood and improves the long-term stability of the coating. This combination of an active agent and passive elements confront the complex challenges of thrombosis to mimic the endothelial layer.

Our multi-action technology enhances device performance for significant periods of time without leaching or use of toxic components.

The Astute® Antithrombogenic Coating provides market leading performance without compromising on safety or quality.

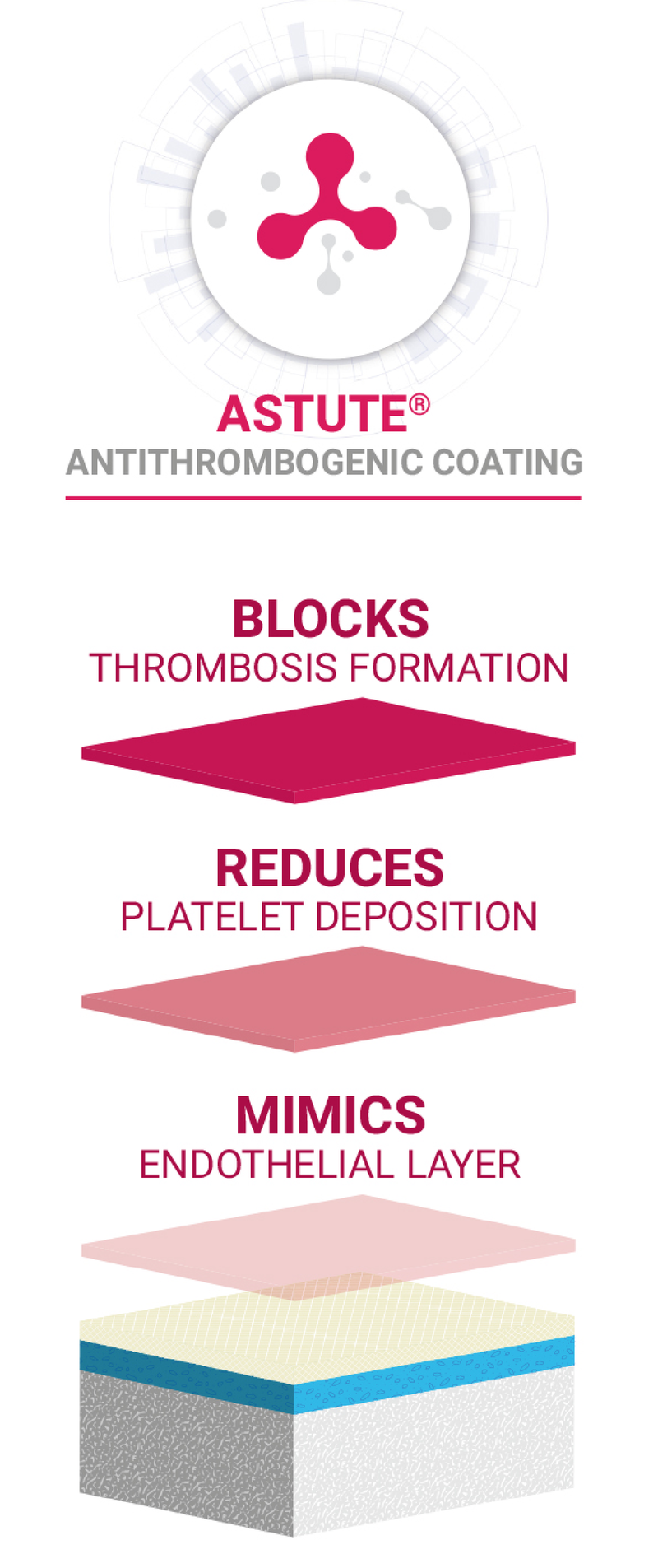

AvertPlus™ Antimicrobial Coating

AvertPlus is a multi-action antimicrobial coating which reduces infections. The non-leaching, multi-action coating, uses contact-kill technology and targets a broad spectrum of bacteria. The contact-kill technology causes cell lysis hinders colonisation of bacteria and prevents biofilm formation. It uses a combination of active agents and passive elements to provide the contact-kill technology, prevents biofilm formation and deposition of onto the surface.

The contact kill technology reduces the bacterial presence and consistently provides high-performance antimicrobial activity throughout the duration of the coating. The active antimicrobial activity is non-leaching and does not use toxic chemicals, such as silver or chlorhexidine. The passive elements hinder proteins and other microbes from depositing onto the service. The combination of these two components reduce bacterial presence, prevent bacterial colonisation on the surface and reduces the ability of biofilm to form.

The AvertPlus™ Antimicrobial Coating is suited for long-term applications without adding risks to the patient. The non-leaching, non-toxic components provide high-performance antimicrobial activity whilst reducing concerns to the user and patient.

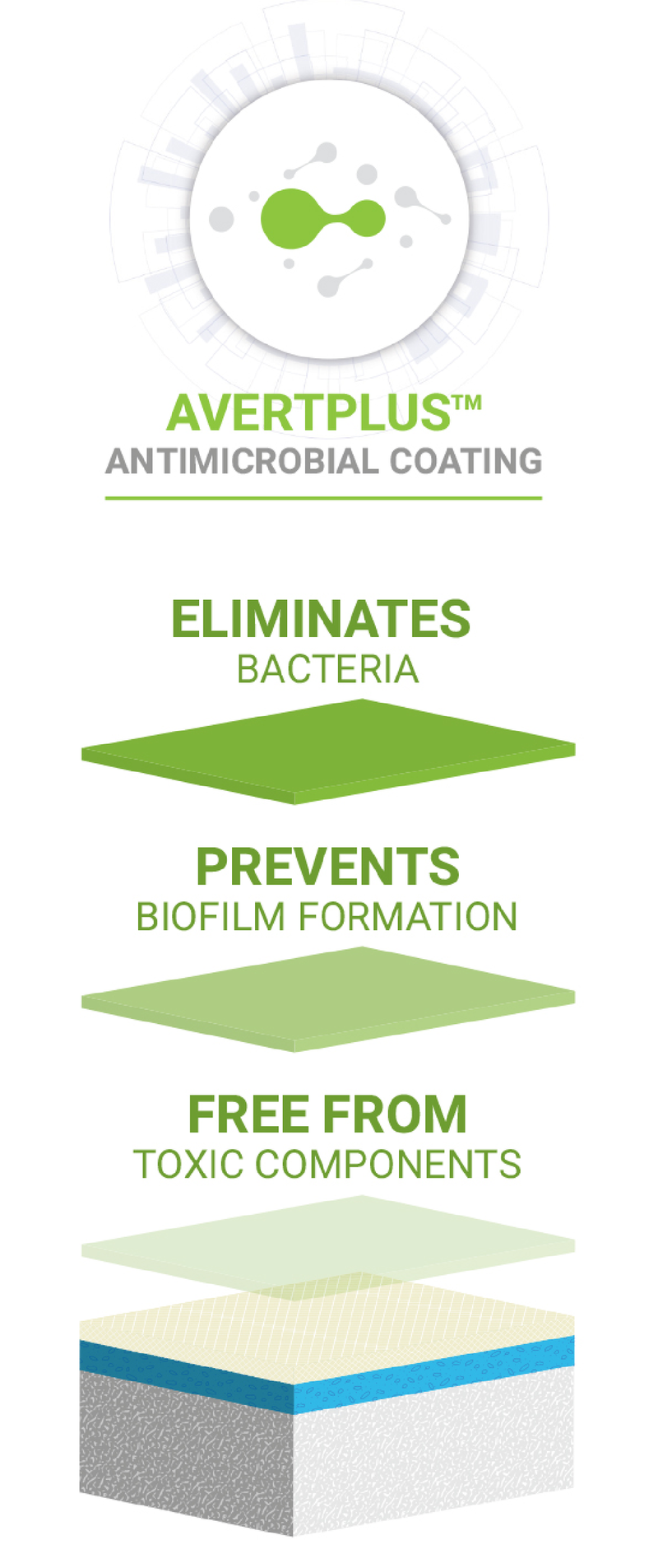

Assist™ Flexible - Hydrophilic Coating

The Assist Hydrophilic Coating is a multi-action coating which significantly reduces the friction on a surface, as well as providing surface protection benefits. Our technology is available in both ultraviolet (UV) cured and heat cured forms to support the application of the coating onto a variety of shapes, materials, and surfaces (internal or external) of the device. The coating is thin and flexible, which enhances its stability and improves efficacy in challenging and long-term applications.

The multi-action coating reduces friction and improves the smoothness of surfaces. The smooth surface created by the coating restricts deposition and adhesion to the coated surface and improves laminar flow of liquids interacting with the coating. This helps to preserve the coated device in its application and reduces deposition or adhesion of components on a coated surface. The multi-action coating is activated instantly through wetting, removing the need to pre-soak the surface. This significantly reduces preparation time and allows increased usage of the device.

The Assist™ Flexible – Hydrophilic Coating uses multi-action technology to improve device insertion and removal, reduces deposition onto the surface to improve patient comfort and safety during long-term applications. We achieve a high-performance, multi-action coating without leaching (particles) or the use of cytotoxic and toxic components.

BioInteractions: Your All-in-One Coating Partner

BioInteractions manufactures all our coating technology in-house and supports our customers efforts with our customer focused Commitment to Care (C2C) services. Our high-performance, multi-action coating technology offers our partners the ability to confront complex biocompatible challenges with a straightforward solution and enhance the performance of their device.

Our expertise has been collected in our C2C services to supports partners’ through their development process. These services consider the challenges with the application of the coating onto the device, the data required for regulatory submission as well as coating services for commercial devices.

We combine high-performance, multi-action technology with customer focused services to ensure the highest quality coated devices are supplied to patients and to help our partners have confidence in our support in their innovation of enhanced devices. We are committed to maintain our quality throughout our high-performance, multi-action coating technology as well as customer focused support services to enable patients to access breakthrough therapies with the highest quality of coated devices.