Less worry,

better care

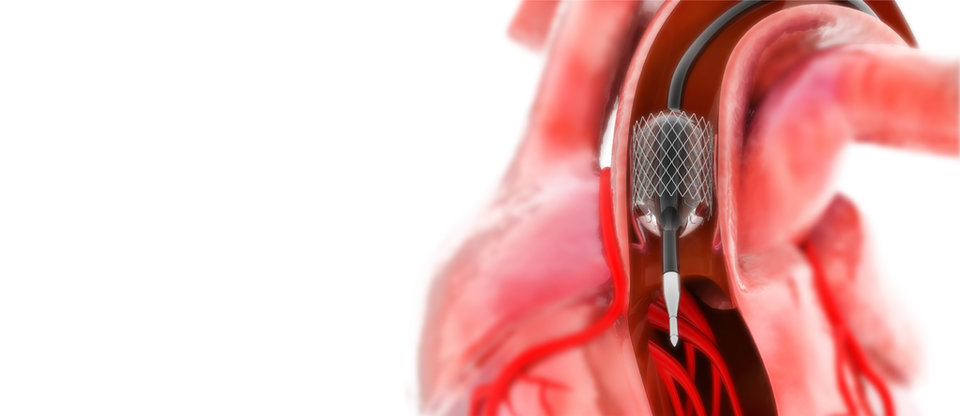

Our Hoowaki MicroGrip™ technology prevents device migration and lets you focus on what’s important: giving the best care.

Medical Applications

- GI and pulmonary stents

- Barrier films

- Cardiac repair devices

- Cardiac assist devices

- Balloons

- Hernia meshes

- Laparoscopic and robotic grasper and stapler jaws

Simplifies Approval

• Formed during existing device manufacturing

• No added chemicals, coatings, or materials

• Made of same material as device

• Never sticky, abrasive, or aggressive

• Offers a simple route for device qualification; often 510(k)

Mission: Solving the most challenging grip or slip problems

High grip, specialty films:

- High grip, non-traumatic, no ingrowth, easy device removal

- High grip, non-traumatic, ingrowth, long-term anchoring

- Medical approved materials such as silicone rubber, TPU, TPE

Biological collection devices: Hoowaki MicroGrip® NP Collection Swab Manufacturing of components with high grip for medical devices:

- Anti-migration components for self expanding stent medical devices

- High grip anchoring components for implanted film-based or mesh devices

- Structural anchoring components for cardiac and vascular devices

- High grip, easy release components for jaws for graspers and staplers

Service of adding micro surfaces to tooling:

- Dies to make low friction tubing

- Molds for low friction, non-tacky, rubber components

- Molds to make high grip components

Prototyping and product development; grip and friction measurement ISO 9001:2015, cGMP, Class 7 clean room manufacturing Represented by PrincipiaMed

400 Birnie Street, Suite C

Greenville, SC 29611

Monday – Friday: 9AM – 5PM

Saturday – Sunday: Closed

Phone: (864)353-6808

Email: alex@hoowaki.com