Company Insight

Sponsored by Alleima

Robotic surgery stands to outpace all other procedure types

As elderly and surgical patient populations grow and medical technology continues to improve, the surgical robotics market is seeing a major boost.

The da Vinci Surgical System (developed by Intuitive Surgical), was the first robotic surgical system approved by the US Food and Drug Administration in 2000, spurring significant investment in medical robotics. Robot-assisted surgery opens the door to more minimally invasive surgical options, the benefits of which include shorter hospital stays, lower risks of complications, less pain, and smaller scars.

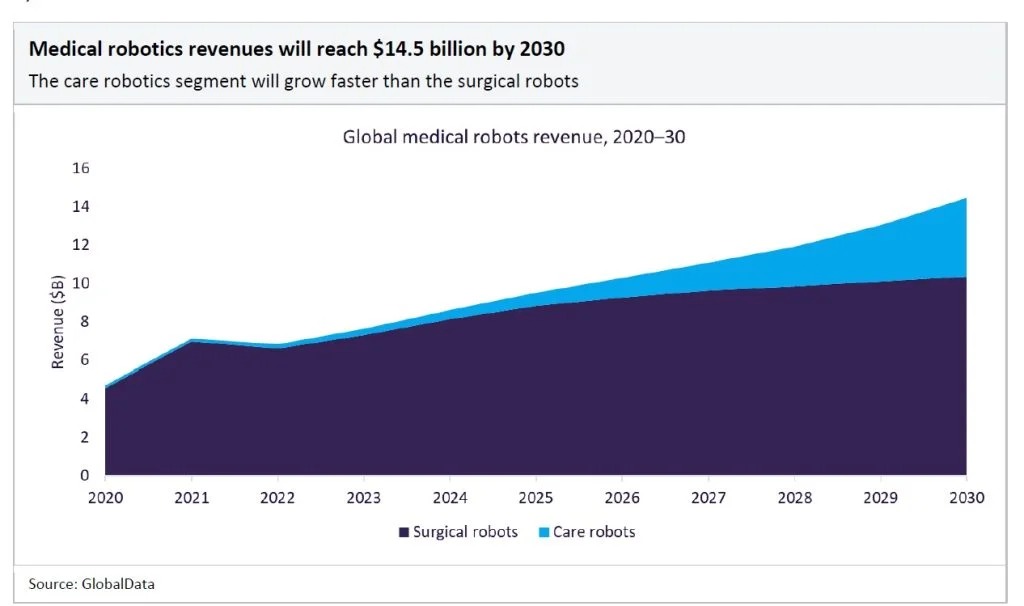

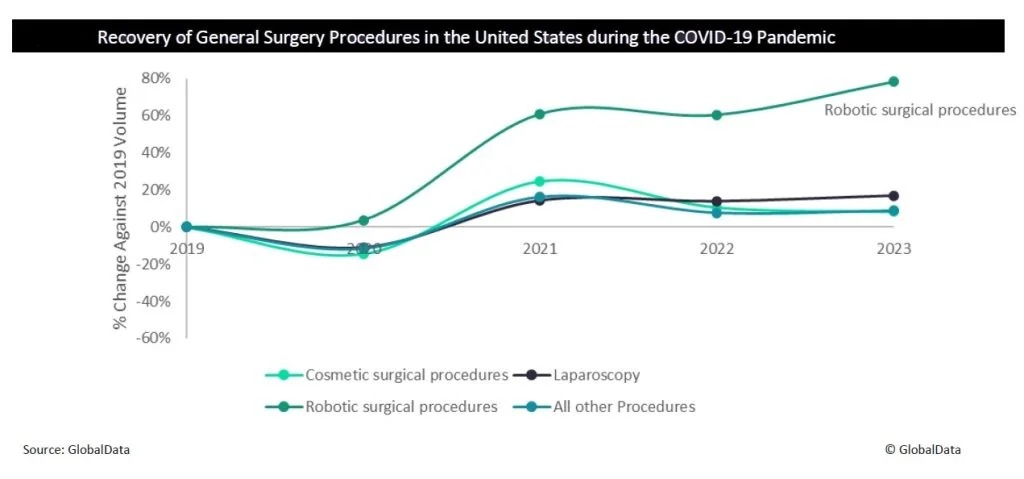

While the COVID-19 pandemic negatively impacted the number of robotic surgical procedures due to the cancellation of elective surgeries in Q2 2020, a significant surge later that year as surgeries were rescheduled made up for the lost revenue. GlobalData predicts that the number of surgeries performed using robotic surgical systems will grow at a CAGR of 10.5% in the US from 2020 to 2030. The overall medical robotics market, which also includes care robots, will reach revenues of $14.5 billion by 2030.

Growth of the orthopedic robots and neurosurgery robots segments will help drive the market and the care robotics segment will grow faster than surgical robots, however, the general surgery segment will continue to lead with an 87% share of the surgical robots market by 2030. Overall, robotic surgical procedures will stand out to outpace other procedure types.

Advances in technologies such as AI and cloud computing are making way for innovation in surgical robotics, which will see better clinical outcomes and reduce the workload for healthcare providers. Furthermore, manufacturers continue to improve robot design so that they are more efficient through innovations in engineering and metallurgy.

According to Tina Deng, medical device principal analyst at GlobalData: “Surgical robots are designed to solve the limitations currently present in minimally invasive surgeries, as well as to improve outcomes in open surgical procedures. These systems are utilised in a variety of surgical procedures, including cardiovascular, general surgery, orthopaedic, neurosurgery, obstetrics, gynaecology, and more. According to GlobalData forecasts, the total surgical robotics market was worth $4.6B in 2020 globally. By 2030, it will have grown at a strong compound annual growth rate (CAGR) of 8.5% to $10.3B, bolstered with the coming marriage of artificial intelligence (AI) and robotics within medical devices.”

“Economic downturns can also create a demand for more cost-effective solutions in healthcare. This could lead to increased interest in surgical robotics systems, as they offer greater efficiency and cost savings compared to traditional surgical methods. Robotic surgery systems allow surgeons to operate with greater precision, reduce complications, and result in faster recovery periods. Because robotic surgery is less invasive, patients typically require shorter hospital stays than they would with traditional open surgery.”

The future of surgical robot manufacturing

“Today, the setup time for a surgical robot in the operating room is still rather long. In addition, the applications are limited due to their rigidity and numerous hinges. These obstacles will be overcome by the next generation of surgical robotics, the soft robotics. These flexible, hingeless robotics will be able to be inserted even deeper in the body and therefore address todays unmet needs. In combination with this new generation of robotic devices, there will be a high demand of extreme flexible instruments which are applied through the working channels. This is exactly where the material Nitinol comes into place and enables innovative endoscopic possibilities,” explains Bernd Vogel, founder of Endosmart, a leading manufacturer of nitinol components, which was acquired by Alleima in 2022. In its new partnership, the company is perfectly positioned to drive innovation in the surgical robotics sector with its expertise in nitinol, an alloy with unique super elastic properties that offers major opportunities to the world of soft robotics, especially compared to the limitations of commonly used materials such as rigid stainless steel. Alleima designs and develops customised sensory medical wire since years, which plays a significant role in the manufacture of smart medical devices. This will be key as surgical robotics continue to evolve and further utilise technologies such as cloud computing and AI.

To find out more about how Alleima can bring innovation to your medical device project visit their website.

Contact information

Alleima Advance Materials

1 Commerce Blvd.,

Palm Coast, FL, 32164,

United States

Tel: +1 386 445-2000

Fax: +1 386 447-5113

Email:ms.spc@alleima.com

Alleima Tucson

2424 East Aragon Rd

Tucson, AZ 85756

United States

Tel: +1 520 495 5927

Alleima Zug

Oberallmendstrasse 20a

CH-6300 Zug

Tel: +41 41 761 63 55

Email: sales@alleima.com

Alleima St Imier

Rue de Beau Site 8

CH-2610 Saint-Imier

Tel: +41 32 942 39 20

Email:info@alleima.com