Company Insight

Sponsored by Watlow

Elevating Compliance and Sustainability in Life Sciences through Standardized Solutions, Electrification, and Industry 4.0 Innovations

Watlow revolutionizes thermal processes in Life Sciences, enhancing efficiency, sustainability, and compliance with advanced electrification solutions. Leveraging Industry 4.0, digital twins, and robust data integrity, Watlow supports OEMs and end users, enabling superior performance, regulatory adherence, and cutting-edge innovation in thermal equipment.

Main image: Reel-to-reel plating of wire. Electroplating allows manufacturers to add a thin layer of metal to a component built from another material.

Watlow leads the way in electrification solutions, elevating the efficiency and sustainability of specialized equipment through advanced thermal processes. Within the Life Sciences domains, our commitment to excellence aligns seamlessly with GxP regulations, embracing the Quality-by-Design approach to ensure superior results.

As we look ahead, Watlow envisions a transformative future for the Life Sciences. Our Industry 4.0 solutions empower laboratories with cutting-edge data analytics and sustainable practices, setting new industry standards.

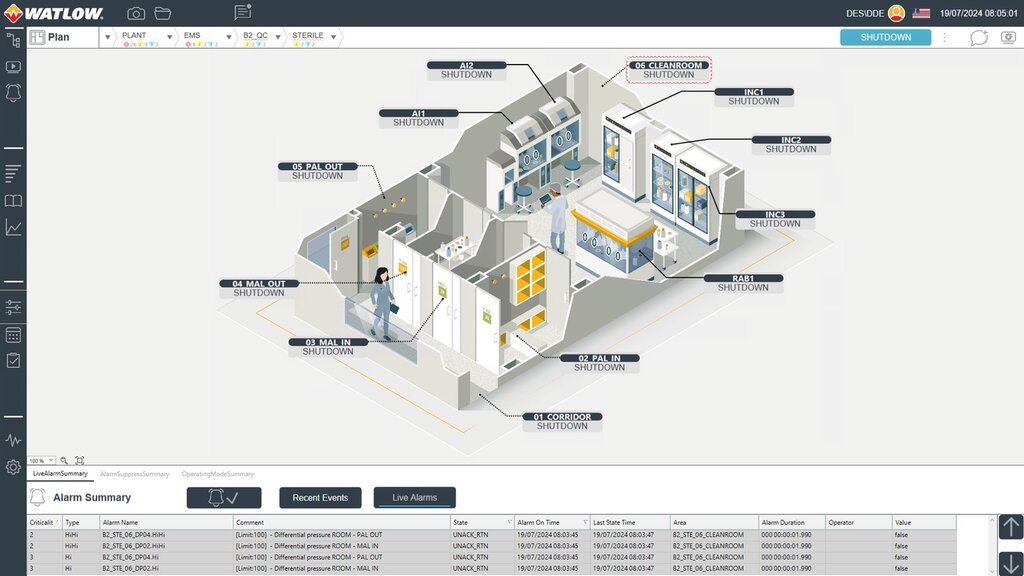

With hundreds of successful Eurotherm* Environmental Monitoring Systems installations across the Life Sciences industry, Watlow’s proven track record underscores our expertise and dedication to fostering a sustainable, efficient, and data-driven future.

Eurotherm Digital Engineered Solutions for Environmental Monitoring Systems – 3D display mode. Scalable architectures from room to enterprise‑level. The user interface is conceived to facilitate usability and reduce errors and alarms; it includes custom 2D and 3D views of buildings/labs/rooms.

Who We Serve

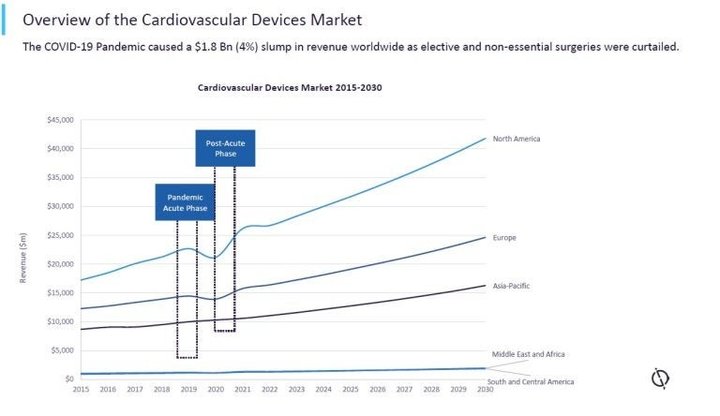

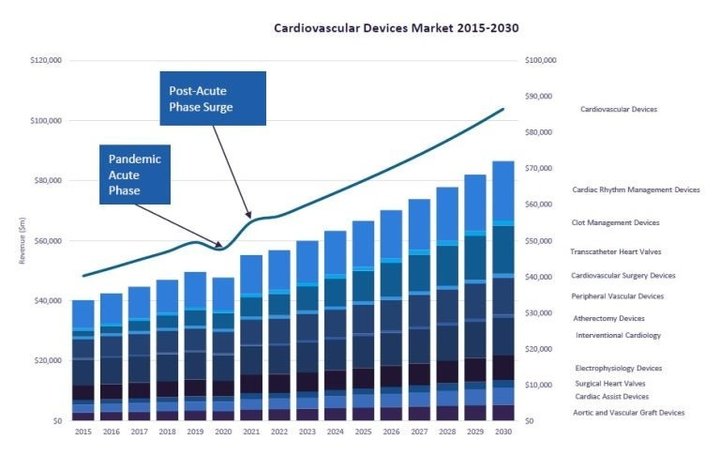

The Covid-19 pandemic caused a global shock to the medical services market. In some areas, this entailed a sharp surge in demand, leading to lowered inventories and a scramble to fulfil orders. In many areas, disruption was in the form of a sudden drop in demand, with elective and non-essential surgeries curtailed. According to GlobalData analysis, some of the market segments that saw the biggest fall were interventional cardiology, cardiac rhythm management, surgical heart valves, clot management devices, and atherectomy devices. As the pandemic progressed, some restrictions were relaxed to enable hospital procedures to resume.

We partner with OEMs crafting state-of-the-art thermal equipment and assist End Users in electrifying their thermal processes or upgrading their control systems. Our solutions are designed to optimize the equipment's time to market, for both the construction and qualification phases and during the operations lifecycle, to enhance efficiency, boost sustainability, and help ensure continuous regulatory compliance. Whether innovating new equipment or revitalizing existing systems, we support your journey toward a more efficient and sustainable future.

Regulatory Compliance

At Watlow, our innovations are grounded in regulatory compliance, and we're passionate about contributing to advancements in:

nanodac™ Recorder Controller. A compact recorder with precision PID control option equipped with digital batch recording and electronic signatures aiding compliance to FDA 21 CFR Part 11 regulation and Data Integrity ALCOA+ principles.

- Data Integrity and ALCOA+: Matching the highest standards of data integrity with the accuracy and reliability required to minimize out-of-spec and maximize throughput.

- Digital Twins for Tests and Innovation: Utilizing digital twins to drive training, testing, and foster innovation.

- On-glass or Paperless Documentation: Embracing modern, efficient documentation methods that eliminate paper use, as per the new ISPE GAMP5 2nd Edition.

- Critical Thinking and Digitalization: Promoting critical thinking and harnessing the power of digitalization.

- Quality by Design and Risk Management: Implementing quality by design and robust risk management in the operations to build a library of best practices and minimize the change management pain.

Excellence in Thermal Efficiency and Sustainability

At Watlow, we excel in delivering improved efficiency and sustainability throughout the operations lifecycle. Our solutions leverage superior heater performance, scalable technologies, and unwavering regulatory compliance. Here’s what sets us apart:

Our Qualifying Strengths:

- Thermal Knowledge and Engineering: Our deep expertise in thermal processes and engineering allows us to deliver precise, high-quality solutions tailored to your needs.

- Reliability and Longevity: We design systems with exceptional reliability and longer operating life, minimizing the need for requalification and reducing downtime.

- Data Integrity and ALCOA Principles: We uphold the highest data integrity standards and adhere to ALCOA principles (Attributable, Legible, Contemporaneous, Original, and Accurate) to enable trustworthy and compliant data management.

- Digital Twins: Through digital twins, we utilize AI and machine learning to create virtual replica variants of physical systems, enabling predictive maintenance and exploring the design of experiment space for enhanced performance.

- ISPE GAMP 5 2nd Edition Critical Thinking: Our adherence to the ISPE GAMP 5 guidelines promotes critical thinking and risk-based approaches in our processes, allowing for robust and compliant solutions.

- Internal QMS and Risk Management: Our internal Quality Management System and proactive risk management practices are designed to uphold the highest quality and reliability in all our offerings.

Comprehensive Support

Watlow is committed to supporting the entire operations lifecycle, integrating advanced technologies like Digital Twins to enhance efficiency and sustainability. Our holistic approach helps to achieve optimal performance, regulatory compliance, and sustainable operations throughout the lifecycle of your thermal equipment.

Watlow Digital Engineered Solutions (DES)

A Digital Engineered Solution is a standardized monitoring and controlling system that integrates the Pharma 4.0 approach, utilizes top-tier technology, and includes pre-prepared compliance documentation. These solutions are designed to simplify compliance processes and minimize risks and costs associated with various life sciences applications such as containment control in laboratory fume hoods, contamination control and environmental monitoring, control and monitoring of sterilizers and freeze dryers, and more.

By merging electrification and regulatory expertise Watlow Digital Engineered Solutions (DES) revolutionized thermal processes, making them safer, more efficient, sustainable, and seamlessly connected. Our solutions start with a foundation of regulatory compliance, quality-by-design principles, and robust risk management strategies.

Key Benefits:

- Cost, Risk, and Time-to-Market Reduction: By embracing the Watlow DES concept, you can significantly cut costs, mitigate risks, and accelerate your time to market. Our innovative approach ensures that your thermal processes are optimized for maximum efficiency and effectiveness.

- Easy to replicate: DESs are structured as a library of modules and documentation, kept continuously current under the strict Eurotherm Quality Management System to reduce the qualification burden and to duplicate the ‘blueprint’ by adding enhancements and personalization with controlled costs and time.

- Innovative Thermal Processing: Our state-of-the-art solutions unlock new potential for your thermal process equipment. Our DES integrates embedded Knowledge Management, promotes Critical Thinking, and simplifies Data Integrity. We also offer advanced tools like Design of Experiment control, Digital Twins, and comprehensive Data Analytics to enhance your operations.

Choose Watlow DES to transform your thermal processes into high-performance, compliant, and future-ready systems.

Contact information

Watlow Plasmatech GmbH

Brennhoflehen – Kellau 156

5431 Kuchl

Austria

Tel: +43 (0) 6244 20 12 90

Email: watlowleads@watlowleads.com

Web: www.watlow.com