ABOUT US

QMEDICS is a young Swiss-based medical device manufacturer founded in 2008. Our long year experience in the medical device industry has made us very flexible and highly capable of finding the optimum solution for every customer specific needs.

Ever since our foundation, we have been based in North-East of Switzerland, a region famous for technical innovations, with an international character and a sense of global trading. At the beginning of QMEDICS’ existence, QMEDICS offered contract R&D, manufacturing as well as OEM manufacturing for medical devices. As OEM manufacturer we developed, produced and supplied a workhorse of a Nitinol stent QM1 with the matching balloon catheter. This was the pride of the company and became the base of the new product portfolio of today.

In 2017 QMEDICS became an independent company with the opportunity to be legal manufacturer of our own new product portfolio and to do direct sales.

Since the know-how, engineers and production of this design are still at QMEDICS we could improve and expand our product portfolio within a minimum of time.

Today the total facility has an area of over 2800m2 of production space, storage areas and offices, including two clean rooms with a total surface of 1200m2. The facility houses sophisticated machinery, EtO-sterilization as well as packaging and labelling equipment. Finally, dedicated, motivated and highly experienced employees.

Even the best strategy can’t succeed unless it’s supported by a strong company spirit. That’s why we at QMEDICS live and foster an Ownership Culture – a culture that encourages every individual in our company to give his or her best in his or her position to help build QMEDICS’ longterm successes.

Our Vision

At QMEDICS we work hard every day to make sure that our guiding principle “striving for excellence every day and constantly seeking to improve the services we offer” is reflected in everything we do.

QMEDICS as a provider of special patient-care products within the medical device industry, we offer global solutions to improve the quality of life

As a medical device company, we embrace the changing healthcare environment and seek to identify and explore opportunities as they emerge. With the best patient care always in mind, we insist on the utmost in quality of products, character of employees and relationships with customers and colleagues. We commit to strengthen our position in the market and being a financially viable company through innovation and continuous improvement

Our Mission

Understanding your business is our business

Our goal is to design, develop, manufacture, and sell state-of-the-art medical products that will improve the lives of patients around the world.

Partnership instead of competition

We manufacture state-of-the-art products, environmentally-friendly and can flexibly adjust our production capacities to your order situation.

Sharing Expertise is our mission and a promise to customers and colleagues to share medical knowledge and expertise for the benefit of patients health.

Our experience and Swiss quality is your guarantee

We are a community and we serve a community. Nothing we do stands alone, everything depends on cooperation and collaboration.

Our History

- QMEDICs was founded in 2008 out of a SWISS holding with different companies, the responsibility within this holding was OEM & Contracted manufacturing with R&D services. QMEDICS’ R&D developed, produced and supplied a workhorse of a Nitinol stent QM1 with the matching balloon catheter.

- The core Technology, Stent & Balloon Catheter manufacturing.

- Material expertise : NiTi, CoCr, Stainless Steel & Tantalum, Poly Amide, Poly Imide, PEEK,PEBA, PC, PUR & PTFE

- In 2017 QMEDICS became an independent company under the Swiss TF holding, which gave us the opportunity to be legal manufacturer of our own new product portfolio and to do direct sales.

- Since the know-how, engineers and production teams of the QM1 stent system are still at QMEDICS we could improve and expand our product portfolio within a minimum of time.

- Our years of experience, with production for other companies gives us a broader view on strategic product development and a reliable production. This experience we now implement into our own Product portfolio.

- Today the total facility has an area of over 2800m2 of production space, 1000 m2 storage areas and offices & two clean rooms with a total surface of 1200m2.

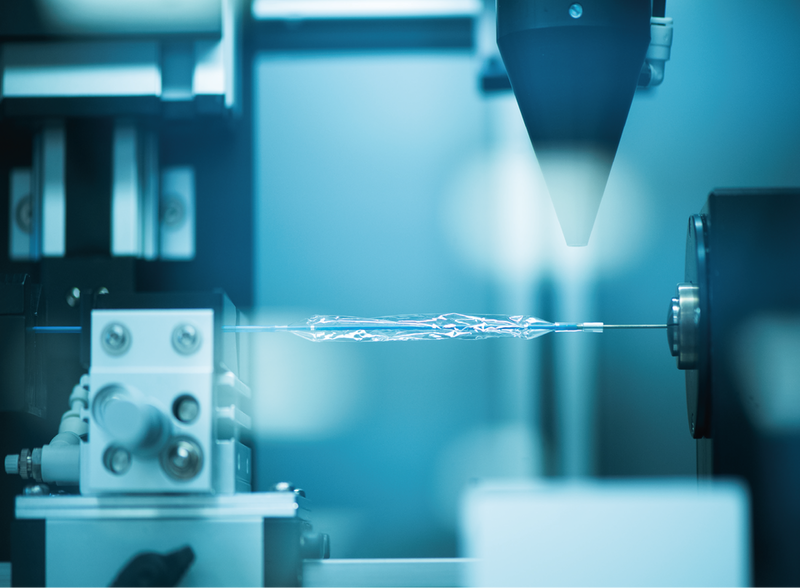

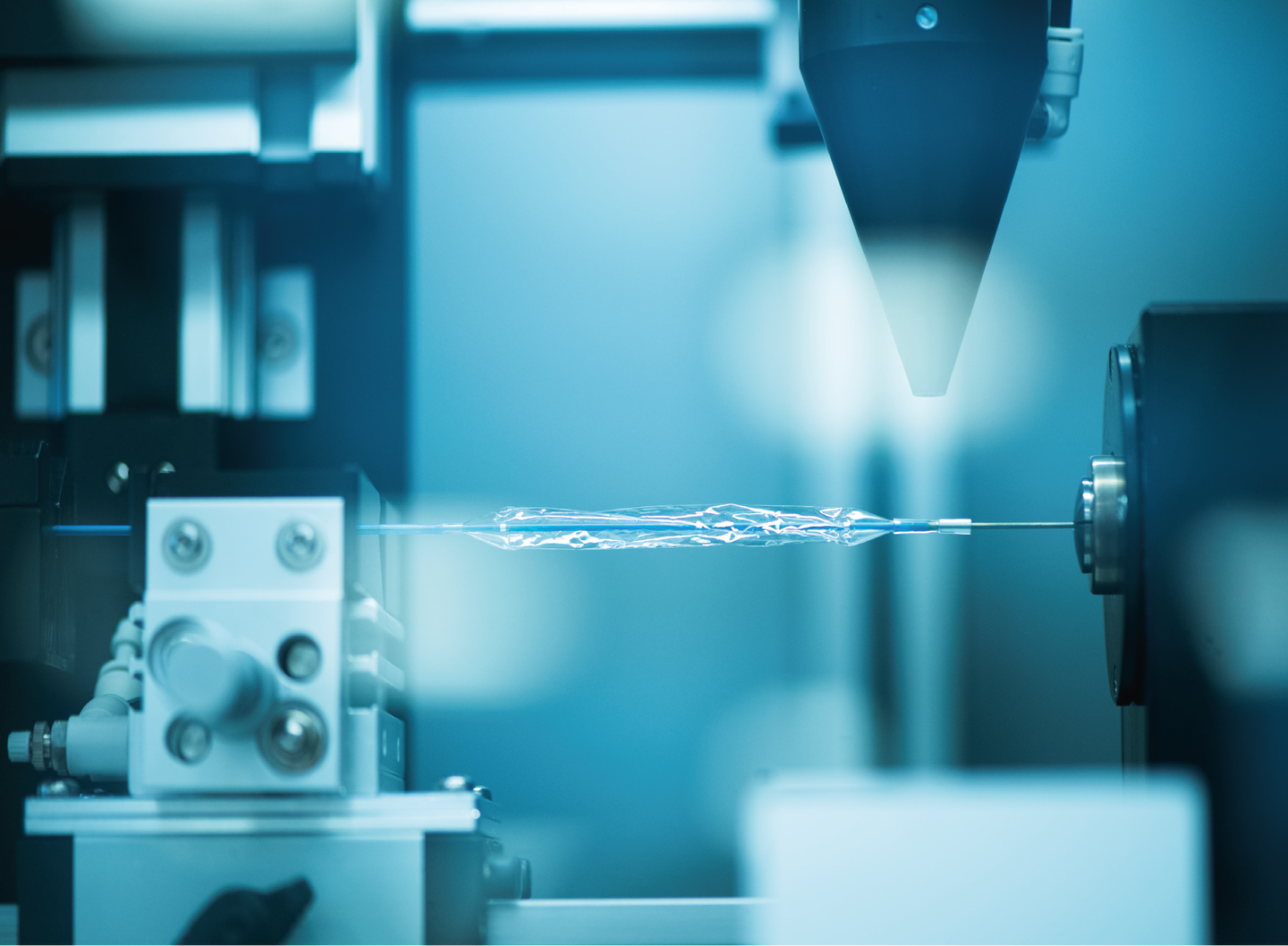

Balloon manufacturing team

The best Balloon manufacturing team “ Bans Team”

With a balloon production of 1500 BDC per week and increasing fast

Indications:

Qmedics PTA balloon catheter portfolio, is designed as a dilatation method for vascular stenoses (transluminal angioplasty).

Contraindications:

Stenoses which cannot be passed by the guide wire.

New product portfolio with innovative properties

- The acts and thoughts of Qmedics are focused on the improvement of the patient´s quality

- of life by offering the best, simplest and technical brilliant solved technology.

- A technology that will have a high performance in treating patients worldwide with peripheral vascular diseases, and with cardio-defects.

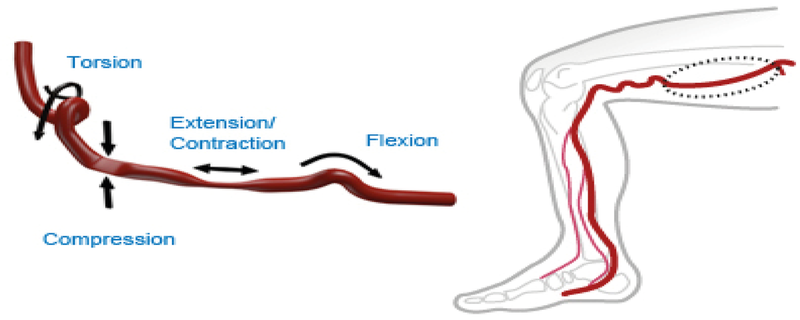

- The Qmedics new stent strategy of is based on an innovative product technology: where every surgeon will get a stent with properties compliant with the lesion and the movability of the art.

- That is why we develop a stent port folio with different properties who can answer to the needs of the lesion classification, artery mobility and level of calcification or obstruction.

Torque

PULL

FLEX

PRODUCT PORTFOLIO

Features & Benefits

Features & Benefits

MANATEE & NAGA & NOVA 0.018“ & 0.035 PTA

To cover the broad range of indication = work-horse balloons

- Large article matrix

- Low sheath compatibility

- Tapered tip for easy passage through extreme, calcified stenosis or occlusions

- Semi-compliant balloon with good RBP

- Memory re-wrapping for easy re-passage

- Big lumen shaft design, quick inflation and deflation

- Simple, intuitive design & construction

Low sheath compatibility

Memory re-wrapping for easy repassage

- Defect-free, concentric balloon tube

- Tube pre-stretch process

- Modern “controlled-strain” balloon blowing

- Slight & short laser weldings

- Thermal, 5,6-wing pleating & folding process