10 microns multilayer provides same protection as 2 cm Epoxy layer or 60 cm silicone layer

Technology Platform

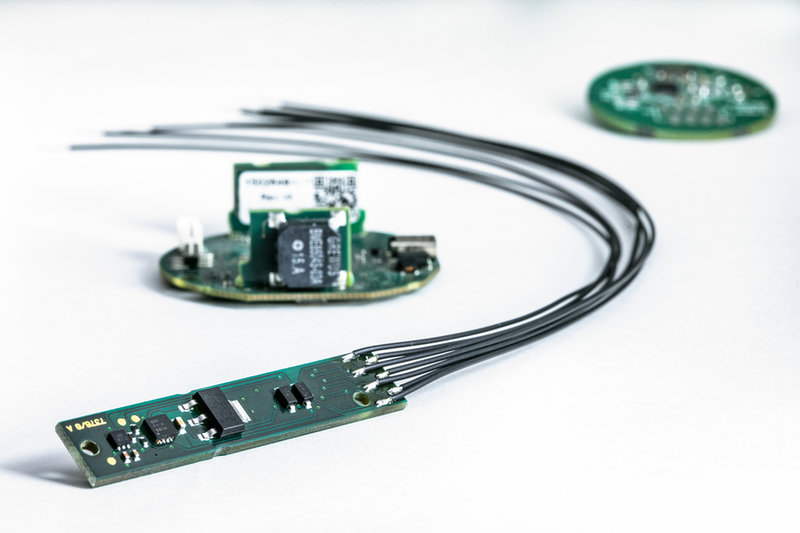

Our coating platform typically combines organic and inorganic layers deposited at ambient temperature via a modified proprietary Chemical Vapor Deposition (CVD) process.

Our single-chamber CVD reactor allows a 3D conformal deposition of Parylene, ceramic or combined Parylene/ceramic multilayers on a variety of substrates and complex geometries.

The proprietary design of our third generation of reactors offers a tight control of the coating’s thickness as well as full flexibility of the layer combinations.

Using our multilayer as a super-flexible super-thin printed circuit board offers exciting perspectives for smart foldable devices.

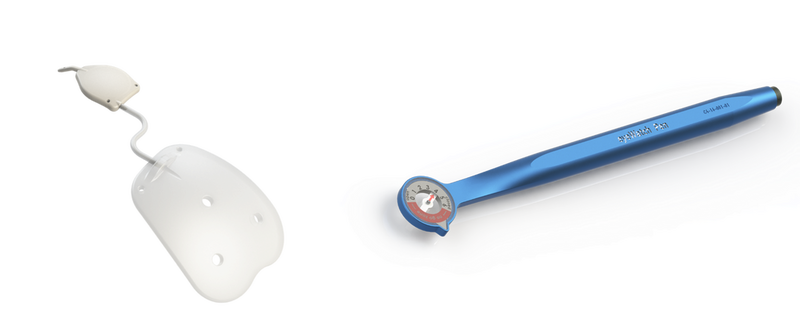

eyeWatch implantable system - Rheon Medical

Applications

Coat-X’s novel technology can replace conventional and expensive metal, glass or polymer encapsulation/protection solutions.

It can be used for many different applications such as: barrier protection for implants and wearables PCBs, encapsulation of corrosion sensitive micromagnets, protection and electrical insulation of instruments…

The technology can be tailored to your application, providing a variety of potential benefits such as:

- Biocompatibility

- Superior corrosion and humidity resistance

- Excellent electrical insulation

- Very low coefficient of friction

- Ultrathin conformal chemically inert interface

Contact us:

Coat-X SA

Eplatures-Grise 17

2300 La Chaux-de-Fonds

SWITZERLAND

+41 32 552 19 20

SEE OUR FLYER

Datasheet

White paper