Micro Moulding

from Microsystems

With years of experience, Microsystems can offer a dedicated micro moulding facility that’s often considered to be one of the most technically advanced in Europe. The experienced and innovative team at Microsystems is on hand to deliver medical micro moulding facilities to produce a number of necessary components within the medical and optical industries.

All-electric micro moulding machines

Microsystems utilise the latest technology that helps in the design and development of the smallest parts possible, with moulding, de-moulding and inspection carried out within the machine itself.

ISO Class 7 production facility

All micro moulding services are carried out within an ISO Class 7 cleanroom to maintain high standards and prevent contamination. Microsystems are also ISO 13485 accredited.

Design and manufacture of injection mould components

Microsystems have extensive expertise in the development and use of micro and nanotechnology in order to deliver required parts for the micro medical industry.

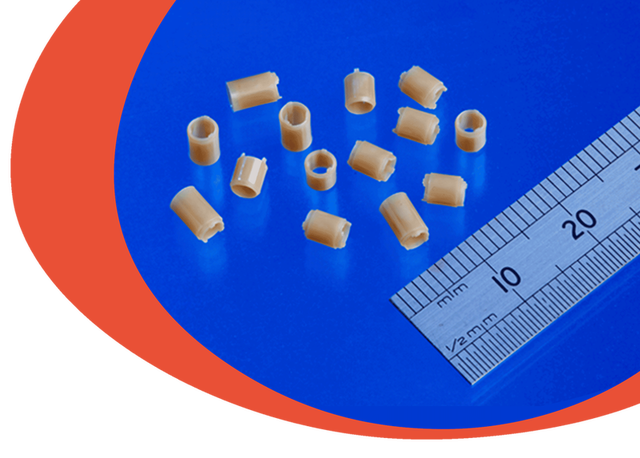

Micro Moulding

for a Variety of Medical Needs

Microsystems can meet the challenges of micro moulding thanks to their in-house capabilities, overseeing everything from design to validation. The team have worked on crucial parts for applications such as cancer treatment and bone implants, with incredibly tight tolerances.

Critical processes taken care of

Microsystems have a well-equipped metrology department to back up its micro moulding processes, ensuring that measurements are accurate down to nanometre resolution.

Variety of parts created in-house

Microsystems have created a number of micro parts for the medical industry, including bioresorbable implants, micro nozzles, PEEK implants and more.

Get in touch with Microsystems today by email or phone.

+44 (0)1942 290 960