Founded in 2002, CWT has been a trusted contract manufacturer of precision medical wire components. Specializing in catheter accessories, cardiovascular valves, guidewires and many other medical and dental devices, CWT has the knowledge and experience to deliver the highest quality in the industry.

While its initial focus was catheter reinforcement coils, CWT’s product and service offerings have only grown since. New capabilities and vertical integration was added with centerless and profile grinders in 2013, followed by further capability expansion in 2018 with the addition of laser marking, as well as 15,000 sq ft of additional facility space in 2021.

- 30,000 sq ft Facility

- 6 CNC Micro-Grinders

- 8 Mandrel Coilers

- Nitinol Coiling

- Nitinol Shape Setting

- CNC Wire Forming

- CNC Point Coiling

- Laser Marking

- Laser Welding

- Plasma Welding

- Ink Pad Printing

- 2,000 sq ft Class 7 Cleanroom

CAPABILITIES

VIDEO

WATCH NOW

Core services currently include ultra-fine coil winding, micro-grinding, wire forms, cleanroom assembly and laser

marking, plus value added services like nitinol shape setting, ink pad printing and laser & plasma welding.

coil winding

micro-grinding

class 7 cleanroom

laser marking

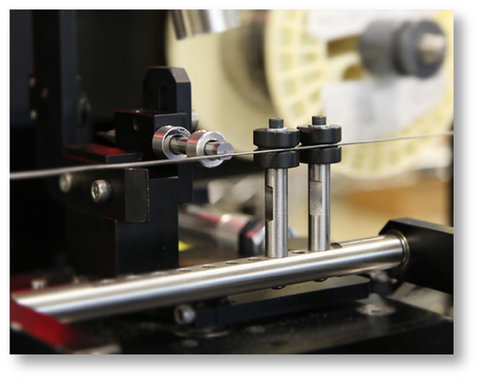

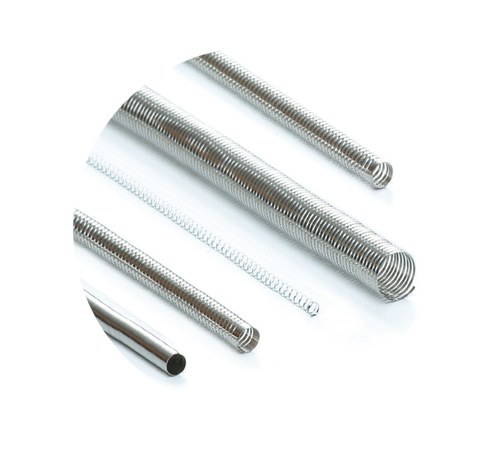

coil winding

CWT provides customized medical wire coiling solutions that meet or exceed design requirements needed by the top OEMs in the medical device industry.

CWT’s technical expertise, unique processes, and wide range of material offerings, such as nitinol, provide an ability to produce complex medical coils with tight tolerances for the most challenging design specification.

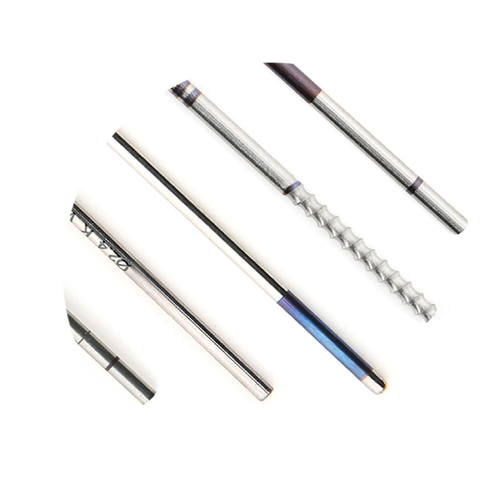

Micro-Grinding

CWT offers medical grinding capabilities to manufacture guidewires, core wires, mandrels, hypotubes, K-Wires, orthopedic pins, needle prototypes, and nitinol components.

Centerless grinding allows for optimal levels of stiffness and flexibility while accommodating tapers of any angle. While profile grinding is utilized for threads, points, and other shapes.

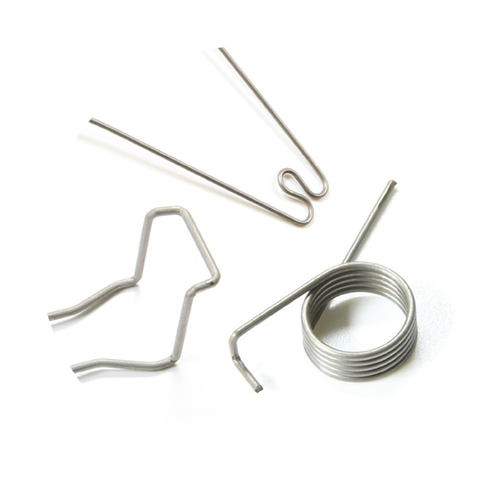

Wireforms

CWT specializes in custom wireforms and components made from precision round or flat wire for medical, dental, and surgical device manufacturers. Laser and plasma welding services can be utilized to provide complete assemblies.

Nitinol Components

Nitinol coils and wireforms offer unique properties which can be superior to stainless steel in certain cases. Its unique elastic, shape memory properties allow for the material to return to various shapes when reacting with external environment changes.

Cleanroom Assembly

CWT’s 2,000 sq ft ISO Class 7 cleanroom provides unique and comprehensive manufacturing, assembly, and packaging capabilities. Products include custom guidewires, stylets, and specialized components for the medical, dental and surgical industries.

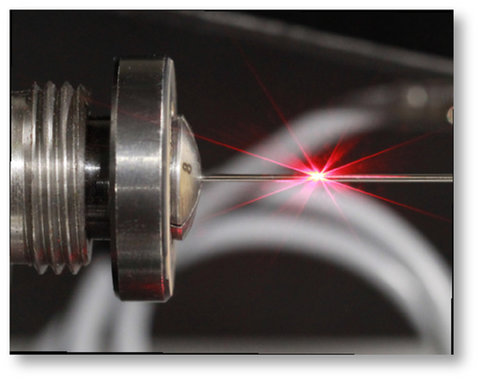

Laser Marking

Laser marking can add unique identifiers such as part numbers, lot numbers, descriptions, and company logos to a variety of parts. CWT can add depth bands to guide wires, k-wires, and pins to present visual feedback to an end user on how far a component may be inserted.

Custom Wire technologies, Inc.

1123 Mineral Springs Drive

Port Washington, WI 53074

Phone: 262-268-9388

Fax: 262-268-9389