From R&D to Final Release

Pave your way to market by controlling quality with smart and robust Sartorius solutions. From simple needles, bandages or surgical instruments to complex drug-eluting stents or pacemakers – medical device manufacturing comes with stringent quality, safety and efficacy standards.

Let Sartorius support you in maintaining reliable and risk-mitigated processes, delivering high-quality products and ensuring regulatory compliance.

Best-fit solutions assist you through the entire development and production process to fulfill biocompatibility, cleanliness, safety and packaging standards.Benefit from precision weighing solutions, ultra-pure water systems and our expertise in filtration, topped with Data Analytics software for straightforward and reliable QC.

With over 150 years of trusted service and proven innovation, quality and reliability, Sartorius can help you bring your life-enhancing medical devices safely and efficiently to market.

Learn more about our Medical Device Solutions

Implants

Surgical Instruments

Diagnostic Kits

Contract Manufacturing & Integration

Wearable & Disposables

Drug Delivery Systems

Medical Device Quality control Made Easy

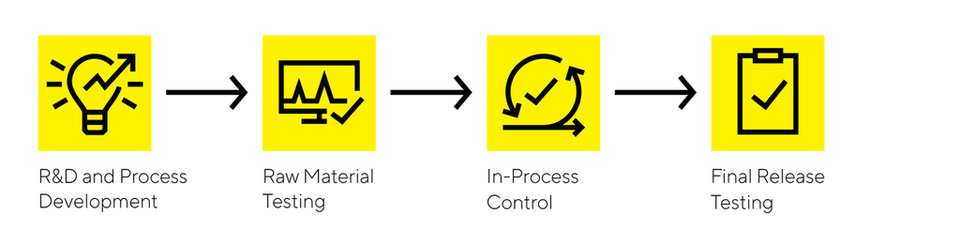

Medical devices - General Process Steps

R&D and Process Development

Quality control starts in the design phase and continues through the whole product life cycle. It is vital activity for successful commercialization, assuring the consistent and compliant manufacturing of life enhancing products.

Discover R&D and Process Development solutions for your application:

Density Check of Solid Material & Liquids

Nanoparticle Concentration

Analytical Characterization - Biocompatibility

Cytotoxicity - Biocompatibility

Data Analytics

Raw Material Testing

The quality of the final product hinges on the quality of the raw materials. To prevent device defects and impairment of patient safety, your raw materials must be stable and safe for use.

Discover the Raw Material Testing solutions for your application:

Density Check of Solid Material & Liquids

Moisture Determination of Raw Material

Particulate Matter Analysis

Analytical Characterization - Biocompatibility

Microbial Testing: Water & Bioburden Testing

In-Process Control

In-process quality control tests are performed at regular intervals to establish that product quality and specifications are met at all stages of production.

Discover the In-Process Control solution for your application:

Check Coatings – Application of Correct Amounts

Moisture Determination

Nanoparticle Filtration of Liquids - Concentration – Detection

Particulate Matter Analysis

Continuous Microbial Air Monitoring

Rinsing & Sterile Preparation

Data Analytics

Counting with Reference Weight

Final Release Testing

Every lot requires tests to ensure each implant is free of contaminants. Error-free assembly, conforming to controlled tolerances, is necessary to avoid malfunction.

Discover the Final Release Testing solutions for your application:

Check Coatings Application

Error-Proof Packaging

Density Check of Solid Material & Liquids

Moisture Determination of Packaging Material

Microbial Testing: Bioburden & Sterility

Analytical Characterization - Biocompatibility

Contract Manufacturing &

Integration, a Partnership to Rely on

Simple. Flexible. Reliable. For Best Performance and Design.

Learn more about our Medical Device Solutions

Customized Solutions, Taylor Made For

Your Individual Process